Bin Activators

HD Bin Discharger

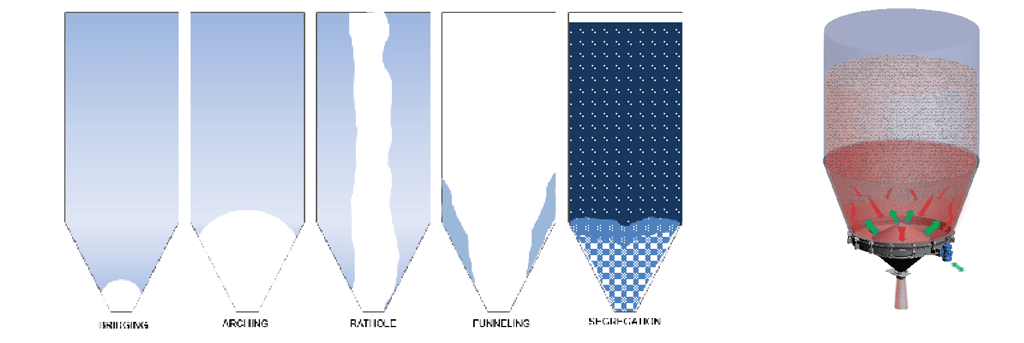

Today’s process industries most often rely on Bin Activators to move dry bulk materials out of storage, on demand. Properly applied, Bin Activators eliminate bridging and ratholing, reduce particle segregation and promote mass flow. They are efficient, convenient and economical and attach to any bin or silo whether new or existing.Because we invented the Bin Activator almost 65 years ago and continue extensive research into bin flow problems and solutions, Vibra Screw offers you an uncommon range of experience.There are more Vibra Screw designed Bin activators in service today, than all others combined, handling some of the most flow resistant materials.

THE ORIGINAL PATENTED DISHED HEAD BIN ACTIVATOR

MODEL HDBD COMPOUND SLOPE BIN DISCHARGER

More Designs and Features Then Anyone Else

Vibra Screw has three basic Bin Activator designs to meet all the various requirements of todays process needs. The original Dished Head design, the Model HDBD which uses a compound slope body and the rolled cone Bin Discharger design.

BIN ACTIVATOR

Vibra Screw has three basic Bin Activator designs to meet all the various requirements of todays process needs. The original Dished Head design, the Model HDBD which uses a compound slope body and the rolled cone Bin Discharger design.

MODEL HDBD

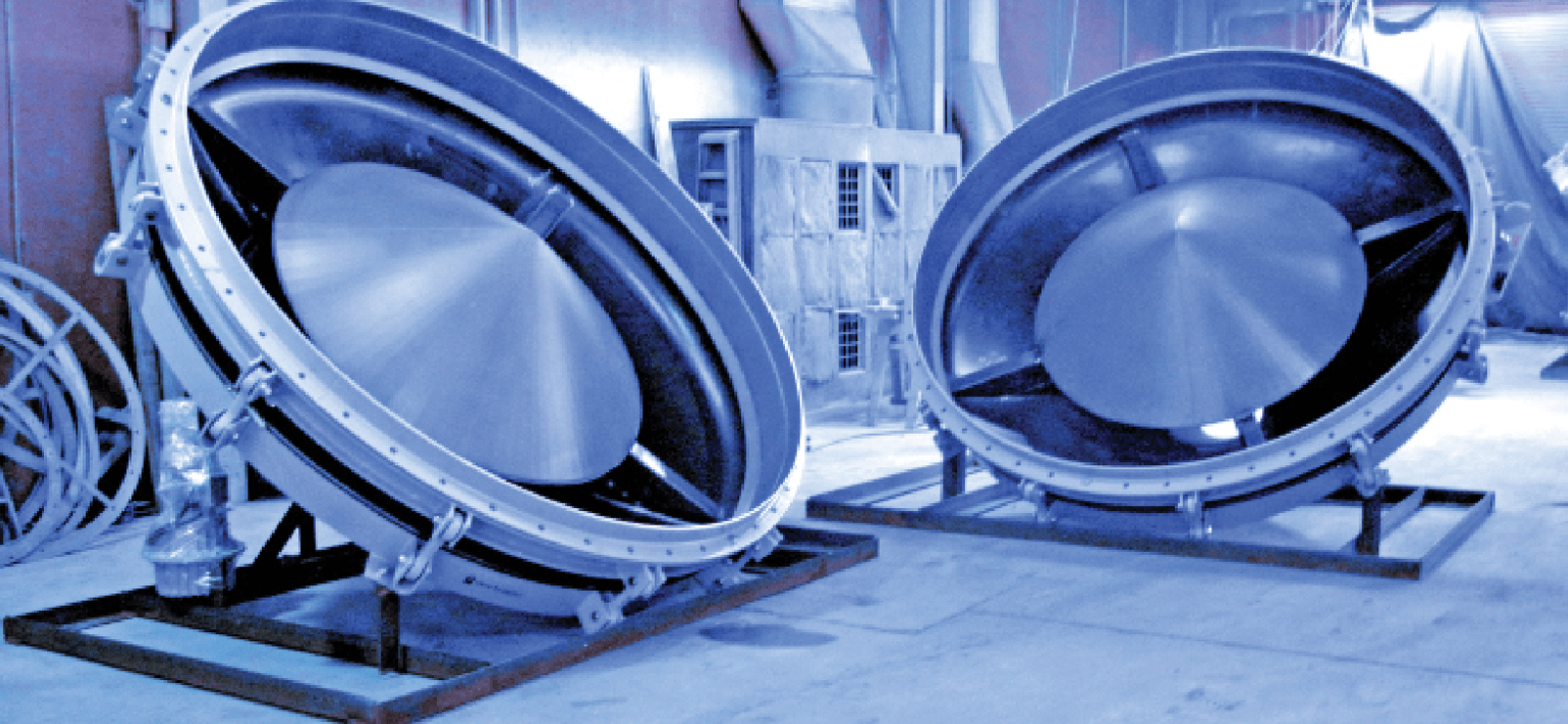

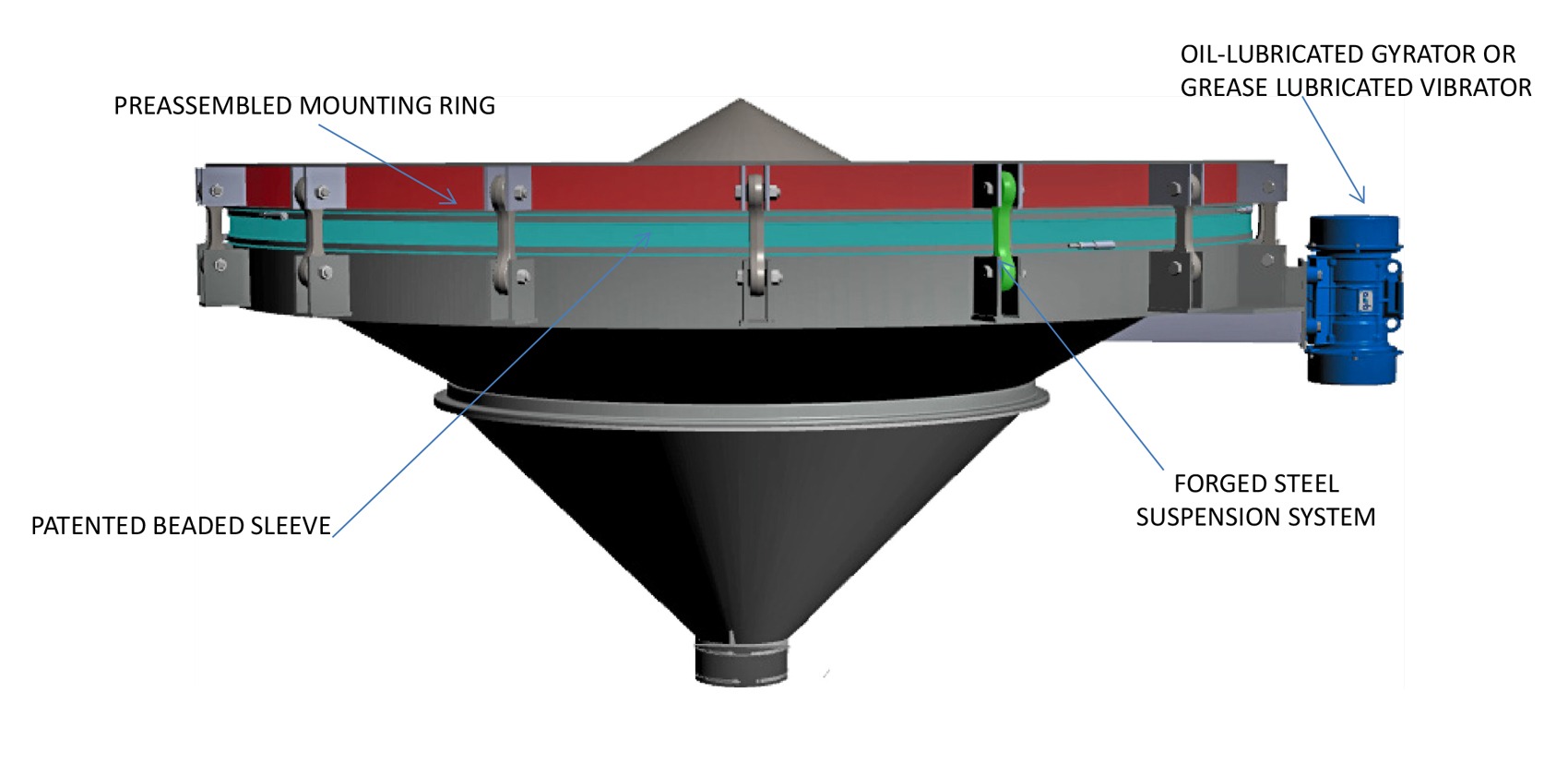

Vibra Screw has introduced a line of Heavy Duty Bin Dischargers for large silos. These machines offer the advantages found only in Vibra Screw’s patented dished head Bin Activators at lower cost.

The Heavy Duty Bin Dischargers combine a shallow upper section with a steaper lower cone. This compound shape eliminates bridging and packing at the discharge outlet that is common with single sloped designs. No secondary baffles required.

Heavy Duty Bin Dischargers are available in diameters from 6’ to 12’. Heavy Duty Bin Dischargers use the same flexible sleeve, vibration isolation system and vibratory drives as Vibra Screw’s Bin Activator so existing customers will find complete compatability in fit up and spare parts inventory

HOW IT WORKS ANIMATION

Click the ![]() to view.

to view.

Click the ![]() to view.

to view.

FORGED STEEL SUSPENSION SYSTEM

Each Vibra Screw Bin Discharger is supported by a series of forged steel hangers, fitted with steel core elastomer vibration isolators. The result is enormous strength along with near total isolation of the Bin Discharger vibration from the bin and surrounding structure.

The forged hangers carry 70,000 [small] and 120,000 [large] lbs load each. This is ultimate capacity [of the steel forging], so BA does not fall off bin. Useable [operating] capacity is determined by the isolators which is approx. 5000 lbs per hanger. So for high headloads we look at the isolator capacity and either add more forged hangers or cable hangers to keep the isolator loading within limits.

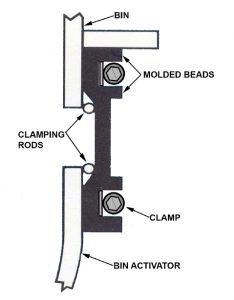

PATENTED BEADED SLEEVE

Molded in one piece with 4 retaining beads, this Vibra Screw innovation has eliminated the problem of sleeve leakage and slippage. Stainless Steel clamps fit securely between the beads and tighten easily and effectively. This sleeve design is so effective it will withstand 10 PSI internal pressure and is standard in all our Bin Discharger designs. Special compounds for high temperature and a flanged bolted sleeve for high pressure are also available.

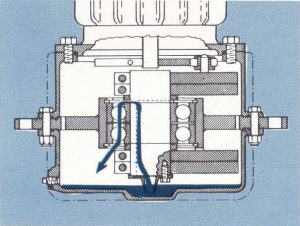

OIL-LUBRICATED GYRATOR OR GREASE LUBRICATED VIBRATOR

Two vibrators to choose from.

Oil Lubricated and cooled Gyrator offered exclusively by Vibra Screw guaranteed for 50,000 hrs of use. The large force-generated eccentric weights are mounted on a massive shaft revolving in oversized, precision bearings. The drive motor is mounted inline with the eccentric weight assembly, but works through a floating coupling so that the motor bearings carry only the motor rotor. Motor life is several times that of typical shafted motor.

Grease lubricated gyrator A special designed rotating motor with oversized shaft, bearings and eccentric weights on the shaft generates centrifugal force. Force output is adjusted by changing the unbalance of the weights.

Bin Activator

HDBD Heavy Duty Bin Discharger

Schematics

| Bin Activator with Pre-assembled Mounting Ring and Greased Vibrator | |||

| 17955-SD | 2′ Bin Activator | DWG | |

| 17959-SD | 3′ Bin Activator | DWG | |

| 17960-SD | 4′ Bin Activator | DWG | |

| 17961-SD | 5′ Bin Activator | DWG | |

| 17779-SD | 6′ Bin Activator | DWG | |

| 17132-SD | 7′ Bin Activator | DWG | |

| 17586-SD | 8′ Bin Activator | DWG | |

| Bin Activator with Pre-assembled Mounting Ring and Oil Lubricated Gyrator | |||

| 17982-SD | 2′ Bin Activator | DWG | |

| 17983-SD | 3′ Bin Activator | DWG | |

| 17984-SD | 4′ Bin Activator | DWG | |

| 17985-SD | 5′ Bin Activator | DWG | |

| 17986-SD | 6′ Bin Activator | DWG | |

| 15597-SD | 7′ Bin Activator | DWG | |

| 15323-SD | 8′ Bin Activator | DWG | |

| 15599-SD | 10′ Bin Activator | DWG | |

| 15320-SD | 12′ Bin Activator | DWG | |

| 16204-SD | 14′ Bin Activator | DWG | |

| Bin Activator w/o Mounting Ring and with Greased Vibrator | |||

| 16706-SD | 2′ Bin Activator | DWG | |

| 16708-SD | 3′ Bin Activator | DWG | |

| 16709-SD | 4′ Bin Activator | DWG | |

| 16711-SD | 5′ Bin Activator | DWG | |