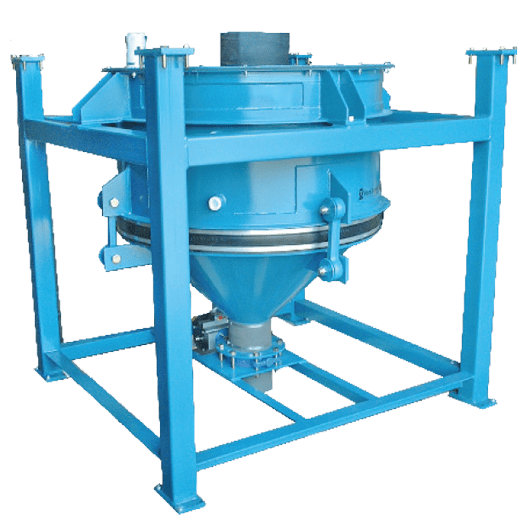

Bulk Bag Unloader

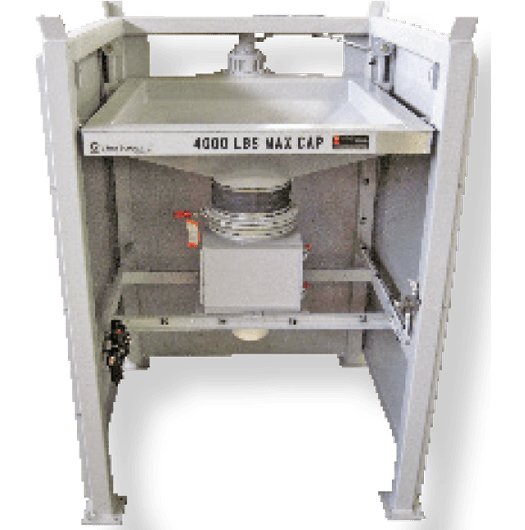

The Bulk Bag Unloader provides a safe, dust-free and convenient way to handle and discharge bulk bags. It is available in eight models to accommodate all styles of bulk bags and bulk bag discharger requirements. These range from a receiving hopper and frame for customer supported bulk bags to a complete bulk bag unloading station. Available options include an integral bulk bag hoist and trolley, manual or pneumatic flow shutoff valve, vibratory agitation to aid material flow and/or a bag massager for more difficult materials, conveyor, load cells and controls for a complete “turn-key” system.

Vibra Screw Bulk Bag Unloaders make handling of bulk bags finally practical by:

- Providing an easy and safe method to lift, support and discharge bulk bags.

- Eliminating dust and spillage associated with other methods of bulk bag handling.

- Permitting controlled, regulated discharge with a variety of feed devices and weight control options.

Features Unique to the Vibra Screw Bulk Bag Unloader

- Bulk Bag Support Hopper – Designed to seat and seal the bulk bag before it is opened. Operator is never required to reach beneath a suspended bulk bag to open the outlet.

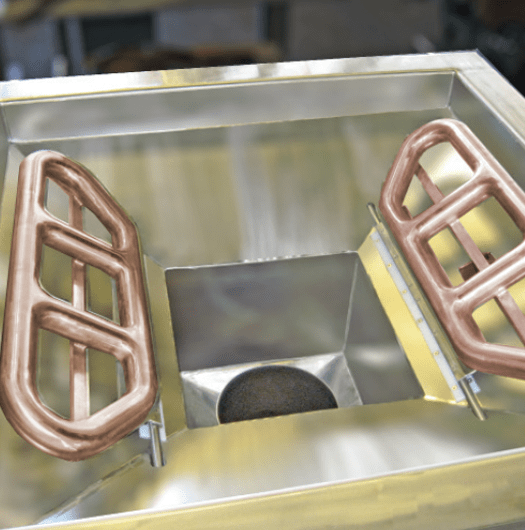

- Dust Control – Standard two-point dust collection. A bulk bag perimeter collection ring traps all dust escaping at bulk bag corners and seams. An outlet system collects dust during bag opening.

- No-Spill Design – Unlike other “open frame”, paddle support designs, Vibra Screw’s collection hopper protects against catastrophic bulk bag spillage due to bulk bag failure, puncture or premature outlet opening.

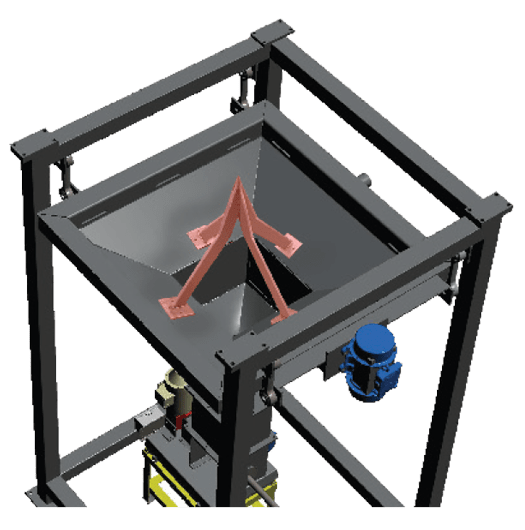

- Vibration Discharge System – Incorporating the same design principles as Vibra Screw Bin Activators, this assures complete emptying of the bulk bag contents without need for repositioning or adjusting the bulk bag.

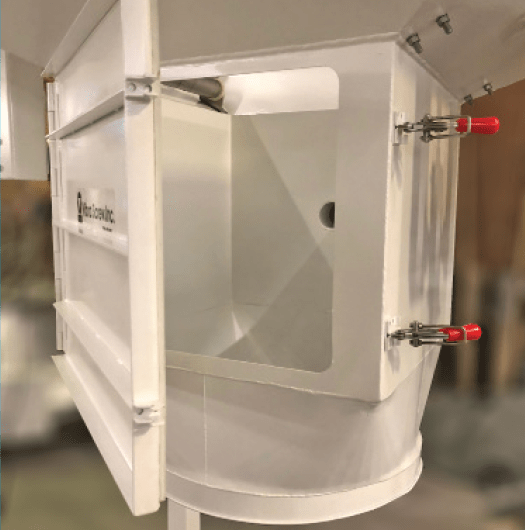

Bag Spout Access Door

Support Frame Enclosure

Massaging Paddles

Bag Slitter

Material Surge Bins

Paper Bag Dump Station

Bag Spout Closer Pinch Valve

Schematics

| Bulk Bag Unloaders | |||

| 17820-SD | Model I-HD | DWG | |

| 17821-SD | Model I-V-HD | DWG | |

| 17822-SD | Model II-HD with hoist | DWG | |

| 17851 | Model II-HD with hoist & FlexiFeeder (models 50-400) | DWG | |

| 17823-SD | Model II-HD with fork lift adapter (without hoist) | DWG | |

| 17848 | Model II-HD with fork lift adapter & FlexiFeeder (models 50-400) | DWG | |

| 17824-SD | Model II-V-HD with hoist | DWG | |

| 17849 | Model II-V-HD with hoist & FlexiFeeder (models 50-400) | DWG | |

| 17825-SD | Model II-V-HD with fork lift adapter (without hoist) | DWG | |

| 17850 | Model II-V-HD with fork lift adapter & FlexiFeeder (models 50-400) | DWG | |

| S103 | Bag Unloader – dust pick up ring | DWG | |

| S107 | Bag Unloader – bag dump station | DWG | |

| S114 | Bag Unloader – bag slitter | DWG | |

| S115 | Bag Unloader – liner tensioner | DWG | |

| S116 | Bag Unloader – iris closure valve | DWG | |

| S118 | Bag Unloader – weigh batching | DWG | |

| S119 | Bag Unloader – pneumatic bag closure valve | DWG | |

| S128 | Bag Unloader – bag spout seal | DWG | |

| S146 | Variable Rate Bulk Bag Unloader | n/a | |

| S159 | Bulk Bag Unloader – flow stimulator paddle type | DWG | |

| 17914 | Bag Unloader – festoon system assembly | DWG | |

Equipment Test Video

Bulk Bag Unloader One Way Bag Splitter

Bulk Bag Unloader Dust Collection & Operator Bag Placement

Bulk Bag Unloader

Pneumatic Knife Gate Valve Operation

The Vibra Screw knife gate valve is available as a convenient way to stop the flow of material from a Bulk Bag. This valve provides a firm, precise and easy shut off for tying off of partial bags should the need arise to change material at any time. It is pneumatically operated and interlocked with the glove box door to assure safe and secure operation. It can be controlled manually by a locally mounted hand lever, or solenoid driven by remote controls while still maintaining the glove box door safety interlock. Material construction options include carbon or stainless steel.