Materials such a diatomaceous earth, lime, certain pigments, etc., spell trouble for even the toughest standard metering feeders. Our specialized screw feeders let you meter materials that tend to pack and clump, especially when moist. Available in six sizes to handle rates from .28 to 600 cubic feet per hour.

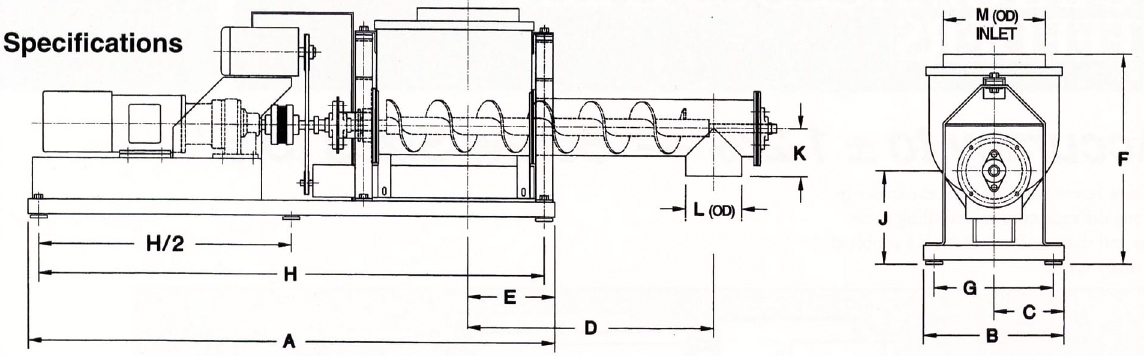

SPECIFICATIONS

| Contact Materials: | Carbon Steel 304 Stainless Steel 316 Stainless steel Special Alloys |

| External Support Brackets: | Carbon Steel |

| Coatings: (Internal & External) | Standard External: Machinery enamel. Optional External: Epoxy Paints. Corrosion-resistant paints. Customer-specified special paints or colors. Standard Internal: Machinery enamel for carbon steel; stainless and other alloys, uncoated Optional Internal: Epoxy paints, Teflon coating, Customer Specified |

| Drives: | Standard: SCR solid state DC drives, potentiometer-controlled, 115-230/1/60, available with modification to accept external signal; 1-5 ma, 4-20 ma, 10-50 ma, 0-6 v. Inverter variable AC drive AC mechanical variable drive AC constant speed |

| Enclosures: | Standard Totally enclosed, fan-cooled Optional Explosion-proof, Class I, Group D Explosion-proof, Class II, Group E, F & G Chemical type, severe duty Totally enclosed, non-vented |

| Sanitary Applications: | Standard All internal seams continuously welded All welds ground smooth All internal survaces polished, #4 finish Food grade gaskets and seals Optional As above, but also includes: Guards, covers, etc. retained with wing nuts for quick disassembly Special TENV motors Structural modifications for ease of cleaning |

| Pressure Applications: | Feeders can be constructed for pressure applications up to 14.9 psig. |

| High Temperature Applications: | Special modifications permit operation up to 350 F. |

| (mm) | Maximum Feed Rates Typical Turndown is 20 to 1 | |||||||||||||

| Screw Size | A | B | C | D | E | F | G | H | J | K | L | M | CU FT/HR | CU M/HR |

| 1 (25.4) | 55 (1397) | 14 1/2 (368.3) | 7 1/4 (184.15) | 15 (381) | 7 1/4 (184.2) | 21 3/4 (552.5) | 12 (304.8) | 52 1/2 (1333.5) | 9 3/8 (238.13) | 2 1/4 (57.2) | 1 1/2 (38.1) | 8 (203.2) | 2.8 (84.2) | 0.1 (190.5) |

| 1 1/2 (38.1) | 55 (1397) | 14 1/2 (368.3) | 7 1/4 (184.15) | 15 (381) | 7 1/4 (184.2) | 21 3/4 (552.50) | 12 (304.8) | 52 1/2 (1333.5) | 9 3/8 (1333.5) | 2 1/4 (57.2) | 2 (50.8) | 8 (203.2) | 8.8 (90.5) | 0.2 (190.5) |

| 2 (50.8) | 55 (1397) | 14 1/2 (368.3) | 7 1/4 (184.15) | 16 1/2 (419.1) | 8 1/4 (209.6) | 21 3/4 (552.5) | 12 (304.8) | 52 1/2 (1333.5) | 9 3/8 (238.13) | 2 3/4 (69.9) | 2 1/2 (63.5) | 10 (254) | 23.0 (101.6) | 0.6 (241.3) |

| 3 (76.2) | 55 (1397) | 14 1/2 (368.3) | 7 1/4 (184.15) | 16 1/2 (419.1) | 8 1/4 (209.6) | 21 3/4 (552.5) | 12 (304.8) | 52 1/2 (1333.5) | 9 3/8 (238.13) | 3 1/4 (82.6) | 3 1/2 (88.9) | 10 (254) | 74.0 (117.5) | 2.0 (241.3) |

| 4 (101.6) | 58 (1473.2) | 16 1/2 (419.1) | 8 1/4 (209.6) | 21 (533.4) | 9 1/4 (235) | 25 1/4 (641.4) | 14 (355.6) | 55 1/2 (1409.7) | 11 (279.4) | 3 3/4 (95.3) | 4 1/2 (114.3) | 12 (304.8) | 200.0 (130.2) | 6.0 (292.10) |

| 6 (152.4) | 58 (1473.2) | 16 1/2 (419.1) | 8 1/4 (209.6) | 29 (736.6) | 10 1/4 (260.4) | 25 1/4 (641.4) | 14 (355.6) | 55 1/2 (1409.7) | 11 (279.4) | 4 7/8 (123.8) | 6 5/8 (168.3) | 14 (355.6) | 600.0 (157.2) | 17.0 (342.9) |

| +based on materials weighing 40 lbs./cu.ft. | ||||||||||||||