VersiFeeder

Volumetric Screw Feeder

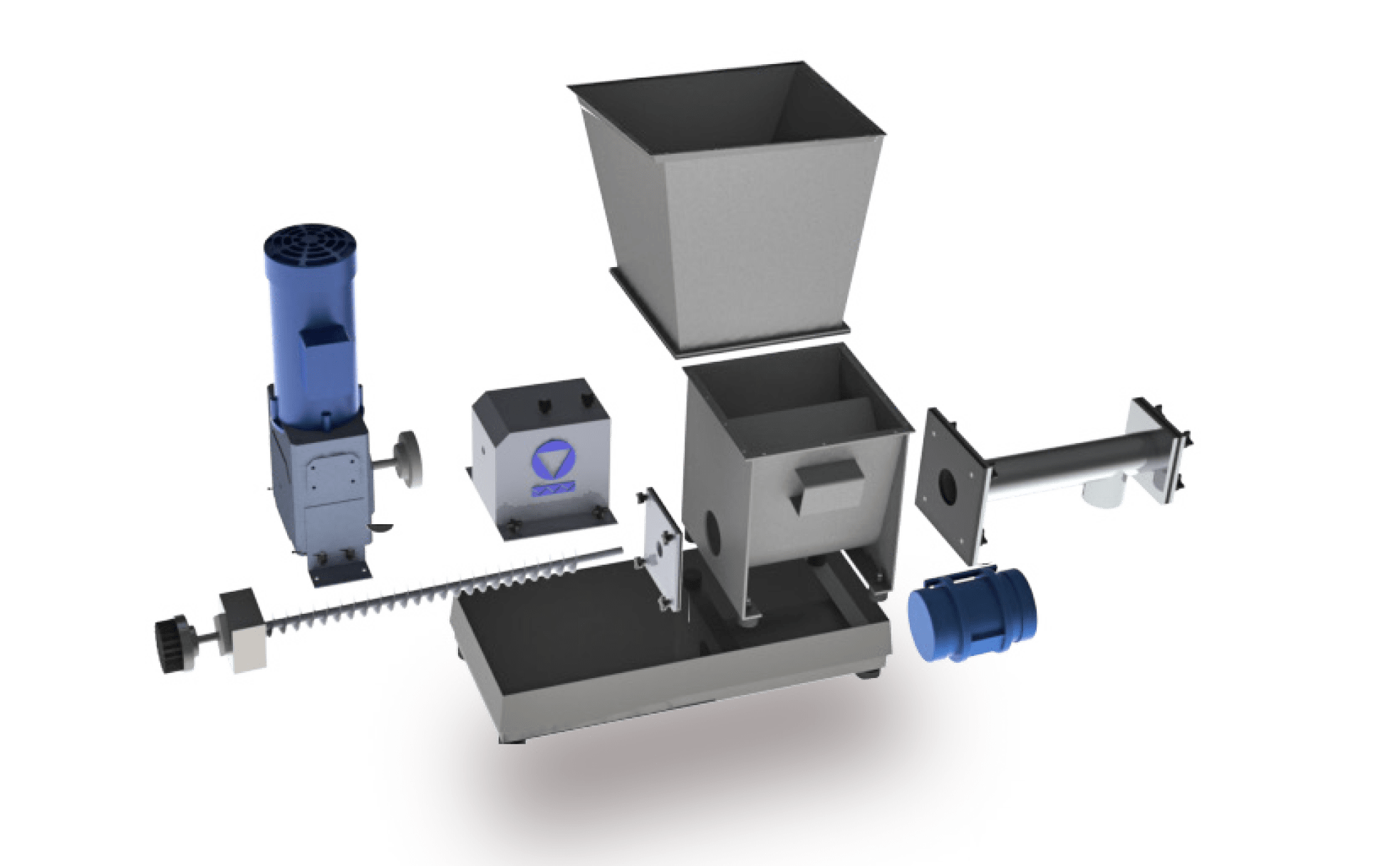

Modular Design

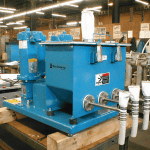

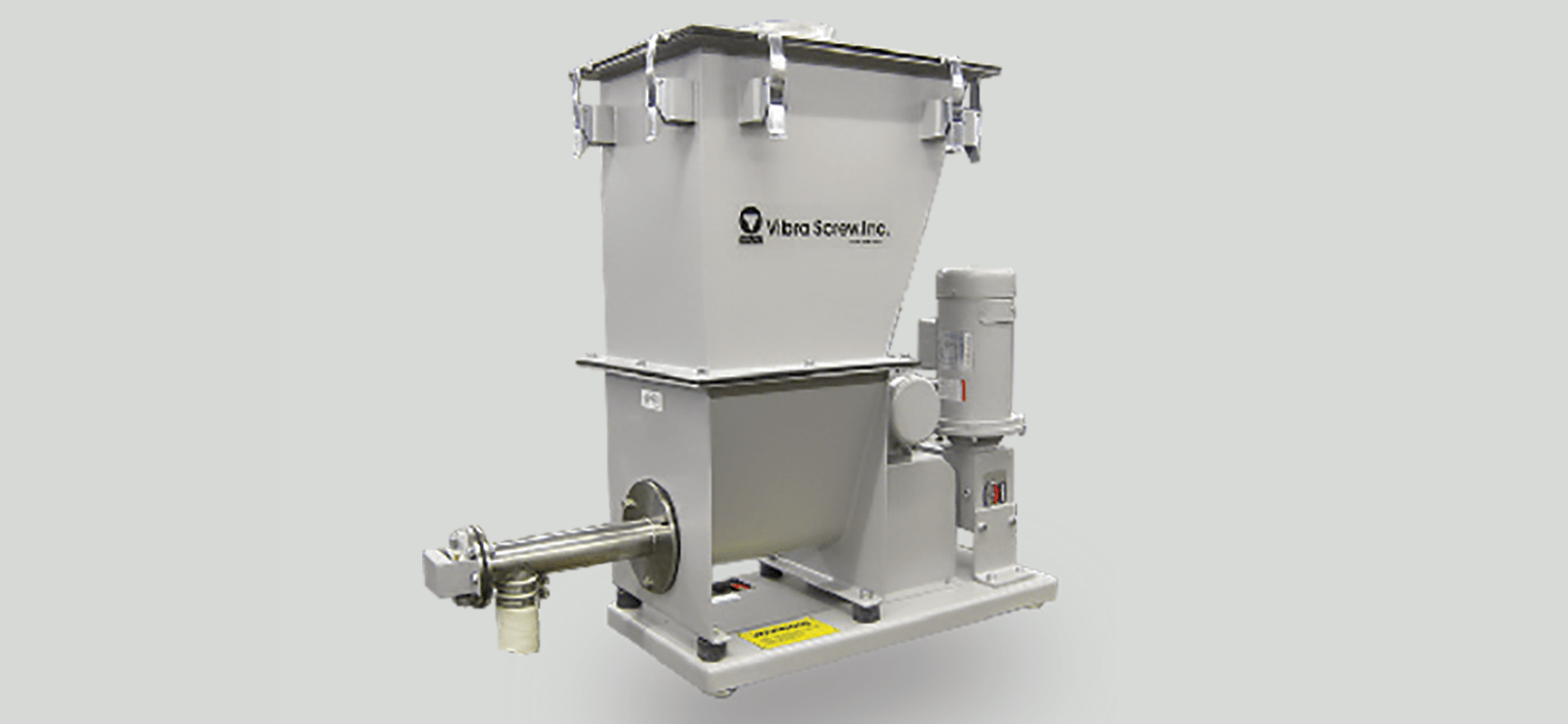

The Vibra Screw VersiFeeder is the first volumetric feeder with modular design, enabling a single unit to adapt to the broadest range of feeding applications.

- A Standard Feeder, with static hopper, trough and feed screw for free-flowing materials.

- An Agitator Conditioner Feeder, with secondary trough conditioning screw for semi-free flowing materials.

- A Vibrated Feeder, using Vibra Screw’s controlled vibration design for non-flowing materials.

The VersiFeeder permits selection of the most economical design required for a specific application, with the unequaled ability to upgrade the design as materials or characteristics change. You’ll always achieve accuracies of ± 1-2% whether with pellets, flakes, powders or fibers.

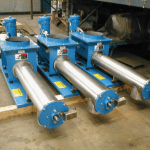

Standard or Sanitary from 0.14 to 600 ft3/hr

The VersiFeeder is available in screw sizes from 1” to 6” and sanitary construction in all sizes. Whether you feed chemicals, foods or pharmaceuticals, VersiFeeder’s wide range of models and options meet the need.

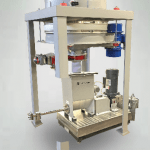

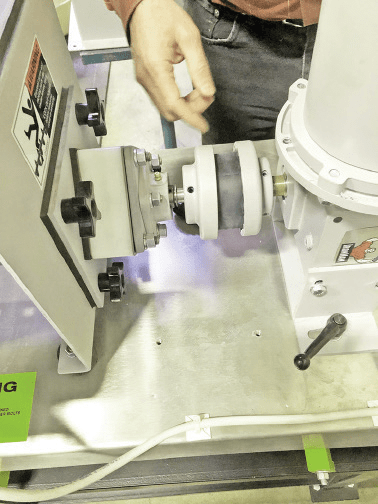

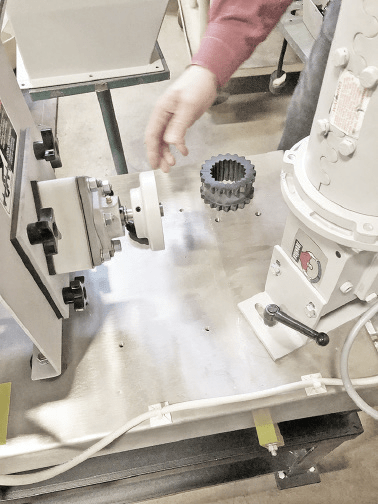

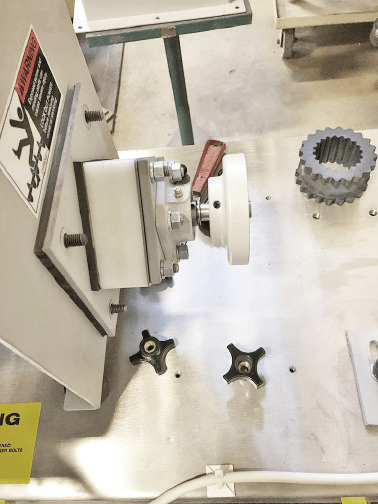

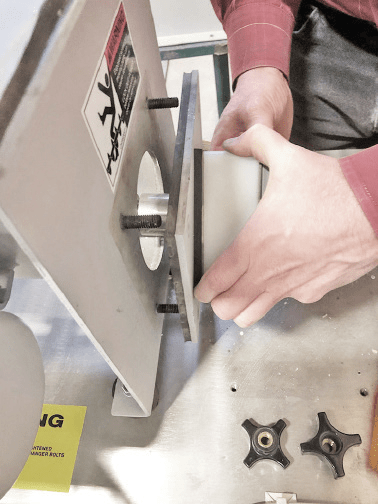

Easy Clean, Tool-Less, Rear Seal Removal

The Vibra Screw VersiFeeder offers optional rear screw removal, permitting cleaning and screw size changes away from the process side. Disassembly is accomplished without tools and in a mater of minutes. All driveline components, gaskets and seals maintain their alignment and integrity during disassembly and reassembly. The screw can also be removed from the front if desired.

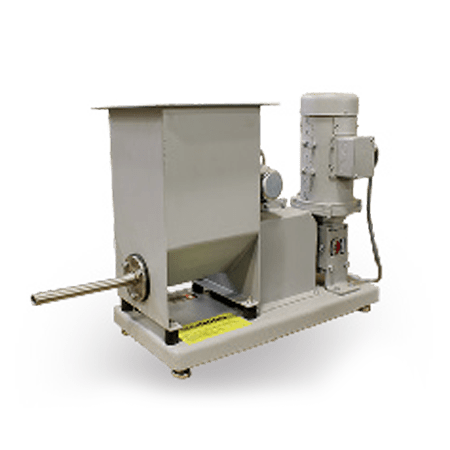

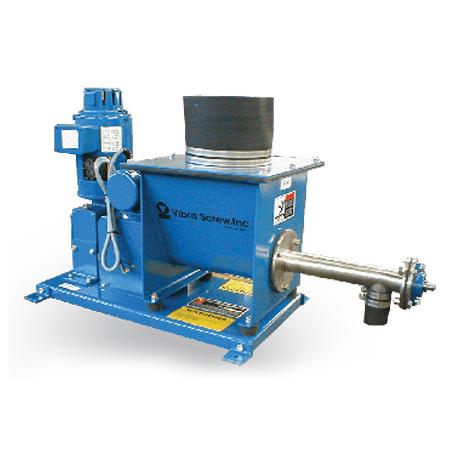

Standard VersiFeeder

Mini VersiFeeder, 1.0 ft3 hopper

Mini VersiFeeder, 0.5 ft3 hopper

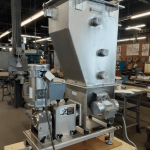

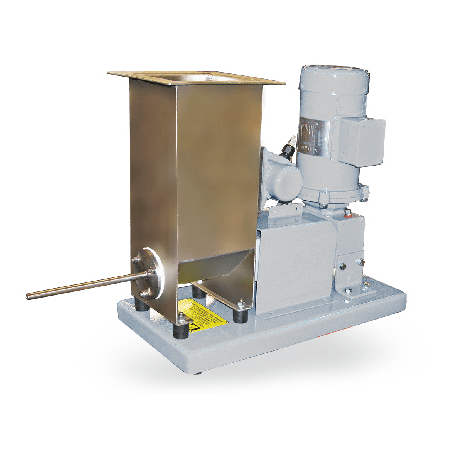

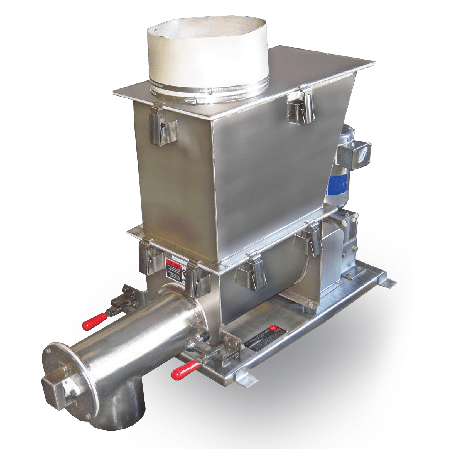

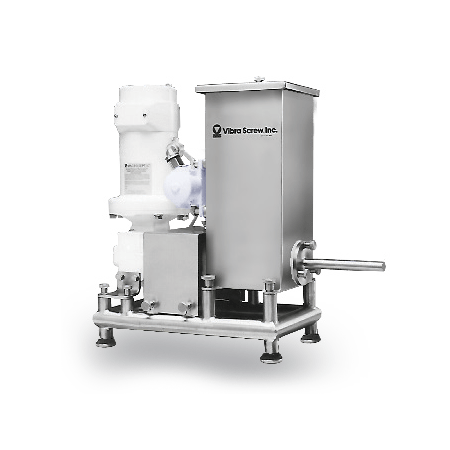

Sanitary VersiFeeder

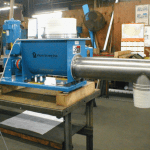

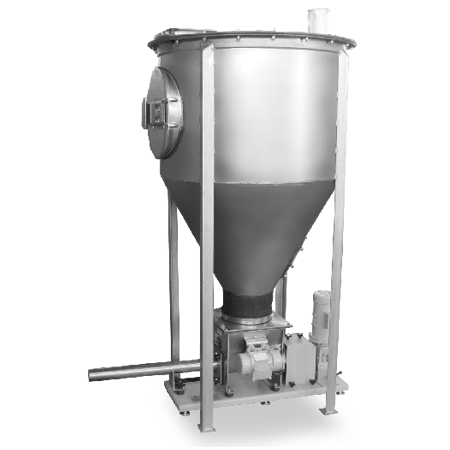

Standard VersiFeeder with free standing 8 ft3 hopper

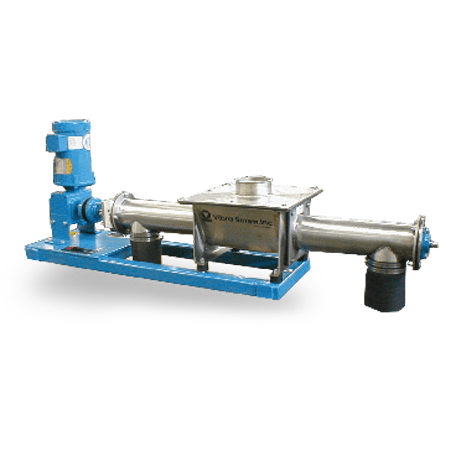

VersiFeeder with Trough Cover, no hopper

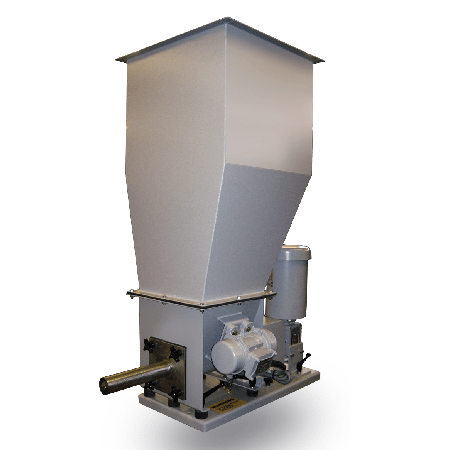

Standard VersiFeeder with 5 ft3 hopper

Bioseptic Feeder

Reversing VersiFeeder

HOW IT WORKS ANIMATION

Click the Play Button in the center of the video to view.

REDESIGNED TOOL-LESS SCREW REMOVAL QUICK CLEAN VERSIFEEDER

Specifications

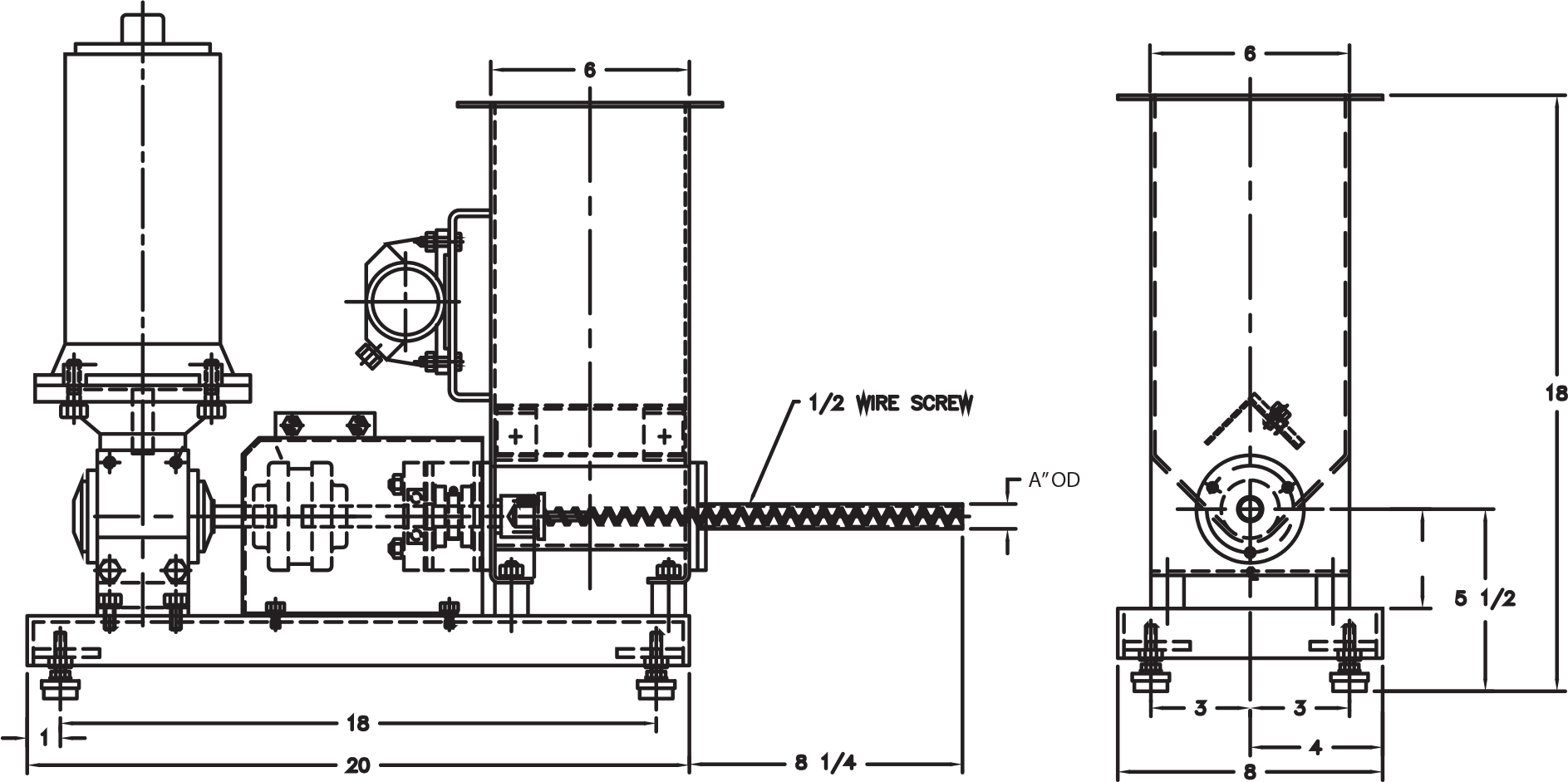

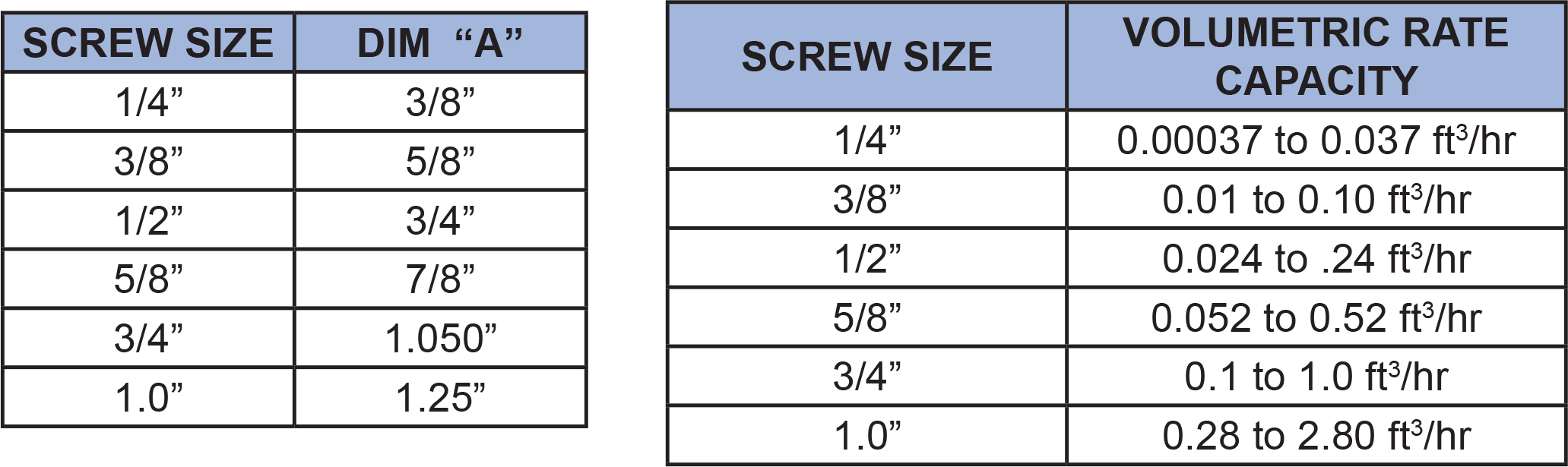

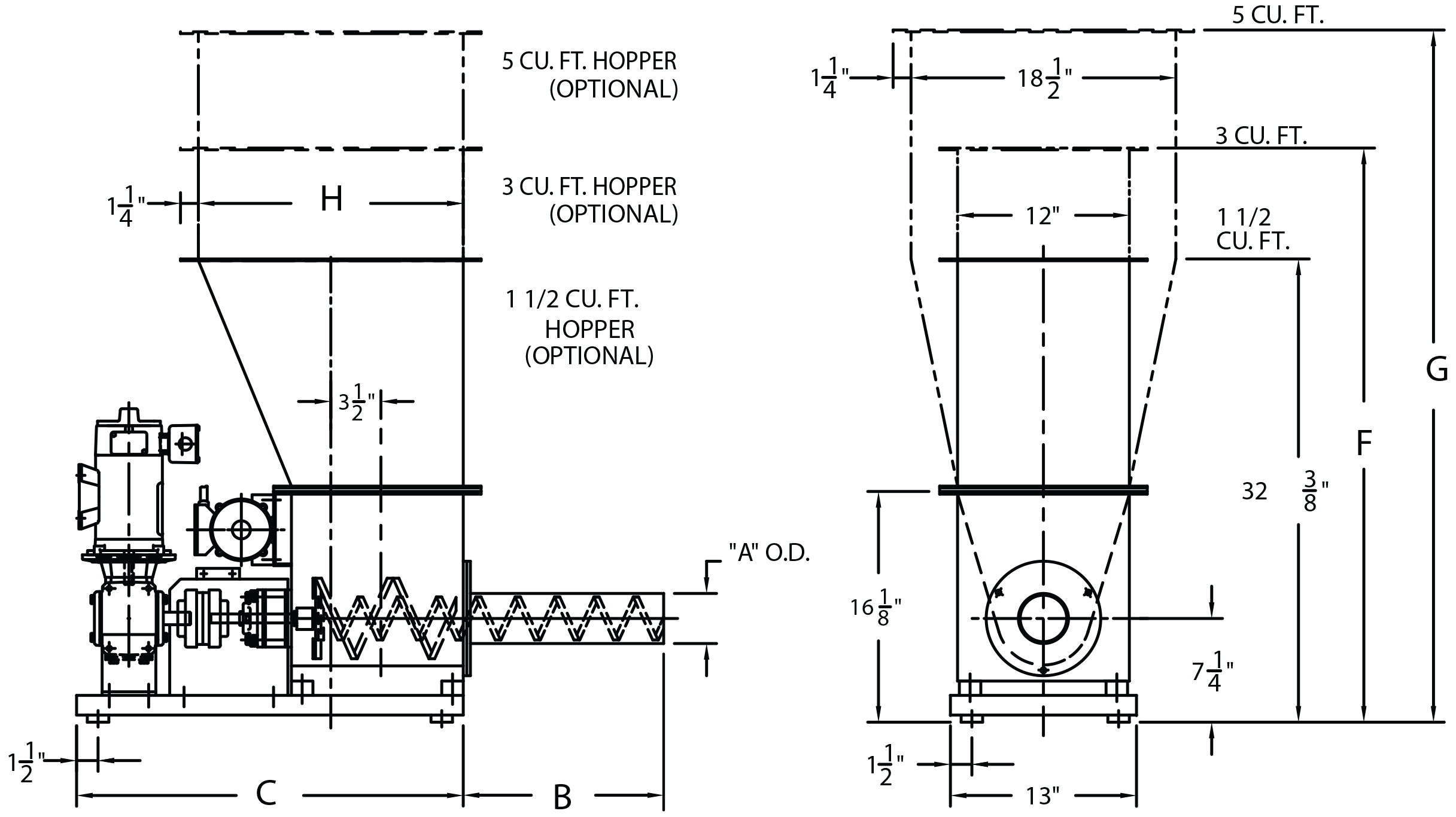

Mini VersiFeeder

1/4 ft3 capacity hopper

Screw Sizes from 1/4” to 0.75”

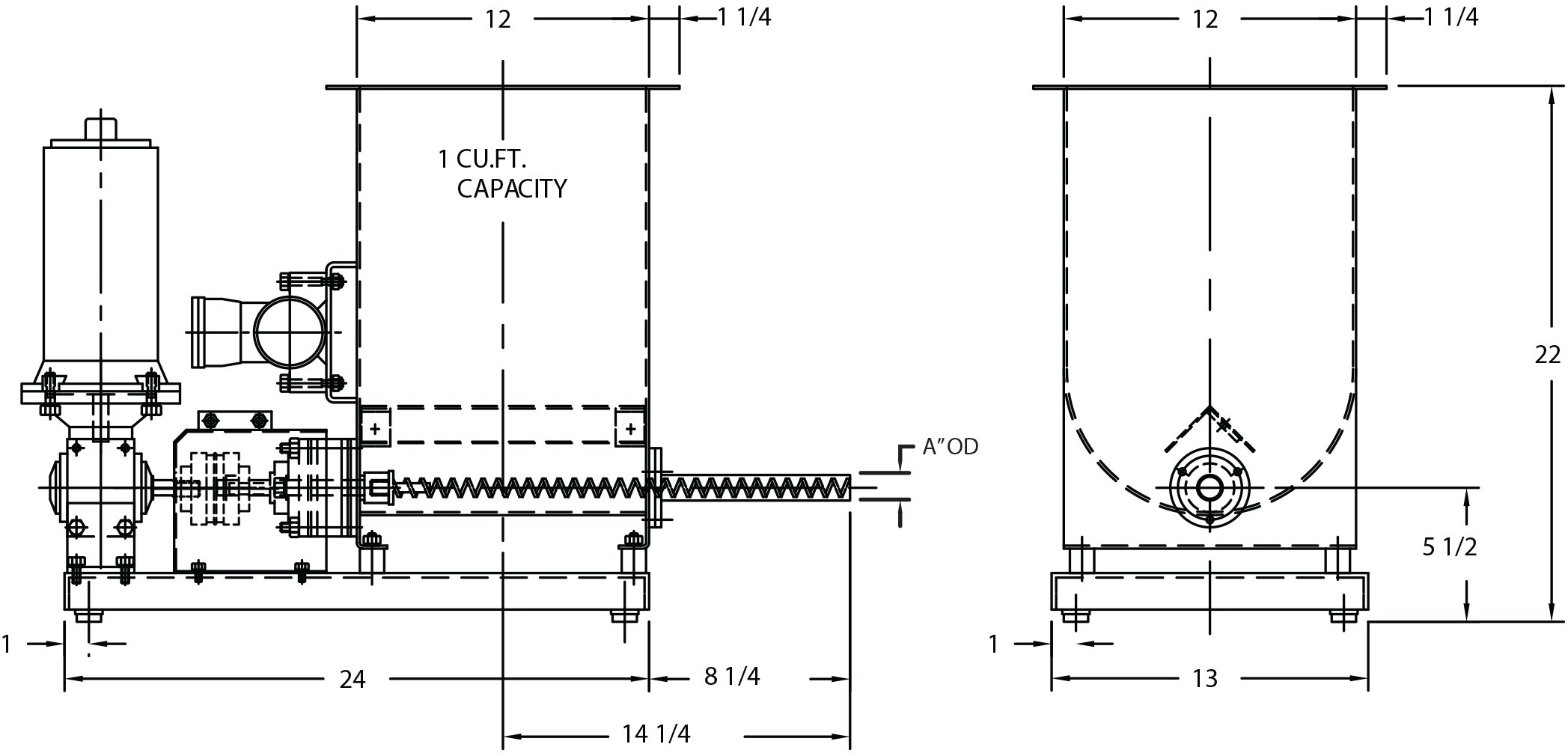

Mini VersIFeeder

1.0 ft3 capacity hopper

Screw Sizes from 1/4” to 1.0”

VersiFeeder

1.5 to 5 ft3 capacity hopper

Screw Sizes from 1.0” to 6.0”

Contact Materials

- Carbon steel

- 304 or 316 stainless steel

- Special Alloys

Coatings

- Standard external-enamel

Optional external

- Epoxy

- Corrosion resistant paints

- Customer specified paint

Standard Internal uncoated or machinery enamel

- Optional internal

- Epoxy paint

- Teflon coating

- Customer specified

Food Grade Applications

Standard:

- All internal seams continuously welded

- All welds gound smooth

- All internal surfaces polished, #4 finish

- Food grade gaskets and seals

- Material contact zone covers & frames equipped with quick disconnect fasteners for ease of cleaning

Optional Features/Equipment

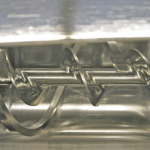

- Vibrator on feed trough

- Conditioning screw in feed trough

- Hopper Cover with inlet opening and vent stub

- Feed tube down spout

Drives

Standard

- DC/ SCR TEFC 115/1/60

- AC Inverter Duty / VFD 460/3/60

Optional

- Analog signal

Enclosures

- Standard: TEFC

Optional:

- Explosion proof

- Chemical duty

- Customer specified

Easy Clean, Tool-Less, Rear Seal Removal

The Vibra Screw VersiFeeder offers optional rear screw removal, permitting cleaning and screw size changes away from the process side. Disassembly is accomplished without tools and in a mater of minutes. All driveline components, gaskets and seals maintain their alignment and integrity during disassembly and reassembly. The screw can also be removed from the front if desired.

Schematics

| VersiFeeder Low Rate Screw Feeder | |||

| S130 | 1/4″ – 3/4″ Mini VersiFeeder w/ 1/4 cu.ft. hopper | DWG | |

| S131 | 1/4″ – 1″ Mini VersiFeeder w/ 1/2 cu.ft. hopper | DWG | |

| S112 | 1/4″ – 1″ Mini VersiFeeder w/ 1 cu.ft. hopper | DWG | |

| 16732A | 1-2″ VersiFeeder w/hopper or trough cover | DWG | |

| 16733A | 3-4″ VersiFeeder w/hopper or trough cover | DWG | |

| 16734A | 6″ VersiFeeder w/hopper or trough cover | DWG | |

| 18048 | 3″ VersiFeeder w/ 3-25 cu.ft Live Bottom Bin | DWG | |

| 18047 | 4″ VersiFeeder w/ 4-50 cu.ft Live Bottom Bin | DWG | |

| 18046 | 6″ VersiFeeder w/ 6-200 cu.ft Live Bottom Bin | DWG | |

| S129 | VersiFeeder with large static hopper | DWG | |

| S106 | VersiFeeder large static hoppers 6-15 cu.ft. | DWG | |

| S102 | Positive shut off disc valve | DWG | |

| S165 | Single bag dump station | DWG | |

| S105 | Hinged VersiFeeder cover | DWG | |

| S144 | Shaft Seal | DWG | |

| S111 | Continuous Mixing Systems – Paper Bag Dump Station | DWG | |

Case Histories

Equipment Test Video

Pressure Modified VersiFeeder Test

Vibra Screw VersiFeeder Assembly Video

VersiFeeder Disassembly Video

Vibra Screw VersiFeeder / Live Bottom Bin Test

Product News

Vibra Screw Improves Efficiency with 3 Gain-In-Weight Feeders

A case study was recently published in ProFood World magazine. Indian Snack Food Processor Improves Efficiency with 3 Gain-in-Weight Feeders “What began as an in-home business two decades ago has grown into an automated company with products now available nationwide in ethnic retail stores.”

Vibra Screw Featured in Waste Water Digest

Forth Worth upgrades feed, mix systems for hydrated lime New feed and mix systems ensure consistent flow of hydrated lime at Fort Worth water treatment plants. In less than 150 years, Fort Worth has grown from a population of approximately 500 to nearly 1 million. To serve people in its North Central Texas metropolitan area, […]

Vibra Screw Feeder used in separation technique for removing gold and silver from the mining solution.

The Merrill–Crowe Process is a separation technique for removing gold and silver from the solution obtained by the cyanide leaching of precious metal ores. This process is currently used at the 10 largest gold producing mines in the free world. As part of the process, zinc dust is added in small amounts but due to […]

VOLUMETRIC FEEDER FOR FUMED SILICA

Fumed silica also known as pyrogenic silica because it is produced in a flame pyrolysis of silicon tetrachloride or from quartz sand vaporized in a 3000 °C electric arc. Fumed Silica consists of microscopic droplets of amorphous silica fused into branched, chainlike, three-dimensional secondary particles which then agglomerate into tertiary particles. The resulting powder has an extremely low bulk density […]

Lime Handling System for Water Treatment

Lime is a manufactured product made from limestone (calcium carbonate) or dolomite (magnesium carbonate). The raw material is processed into quicklime and hydrated lime. Since it is alkaline, it is used to adjust the pH of both drinking water and wastewater. Getting ready to ship a small water treatment lime handling system. The storage bin […]

Mini Feeder Line Screw Size and Hopper Capacities Expanded To Handle Higher Feed Rates

Vibra Screw, Inc., a leading manufacturer of equipment and systems for precision processing of dry bulk materials, has announced expansion of screw and hopper sizes in their highly successful line of Mini Feeders for dry material feeding.The new size ranges (screws are now available up to 1” maximum and hoppers up to 1 cu. ft.) […]

Packaged System Simplifies Sorbent Feed in Continuous Water Treatment Systems

Vibra Screw, Inc., a leading manufacturer of equipment and systems for precision processing of dry bulk materials, has introduced a completely packaged system that simplifies the wetting and metering of activated carbon in water treatment systems. Vibra Screw’s continuous duty system includes a bulk bag unloader, volumetric screw feeder, educter and cone wetting unit for […]