Water and Air

Pollution Control

Our innovative and technical experience in the waste water and flue gas / smoke treatment

allow us to offer solutions for turnkey installations or integration of new equipment into your process

lines. Our many years of experience in storage bin design, discharging, volumetric and gravimetric feeders, mixers and pneumatic conveying allow us to offer complete system packages.

- Soda Ash

- MagOx

- Lime Slurry (Quick/Hydrated)

- PAC

- Cement

- Polymer

- Other Bulk Chemical Handling Systems

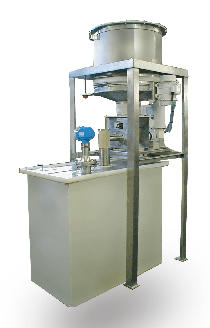

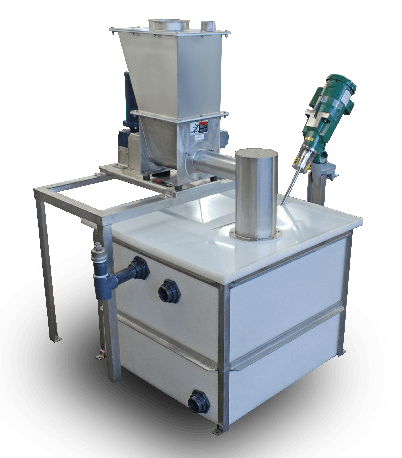

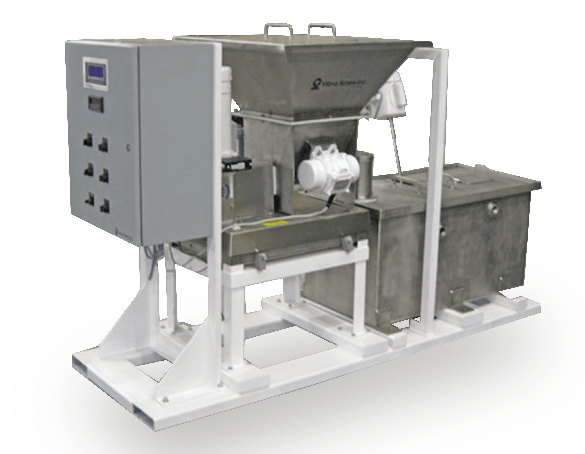

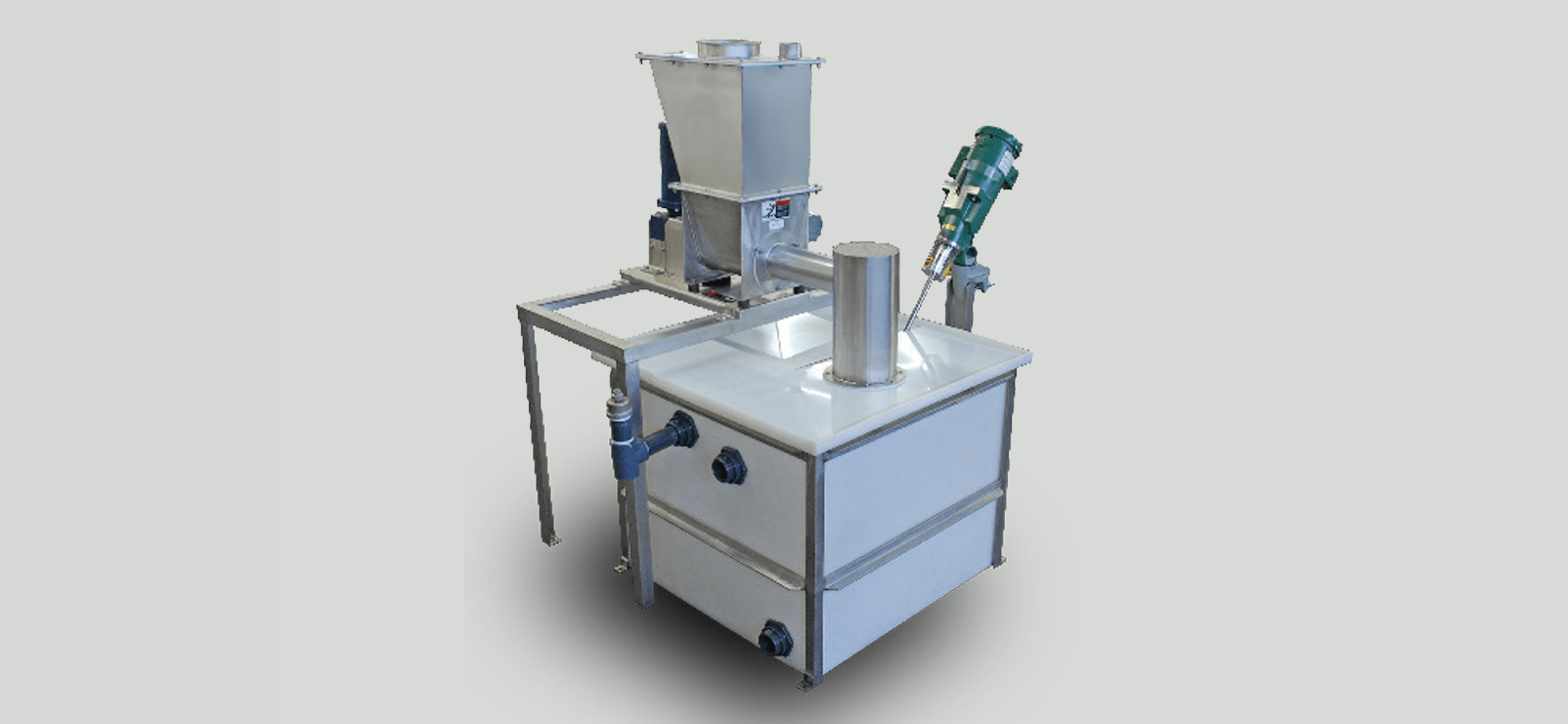

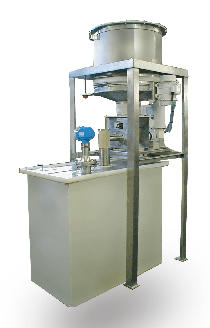

POLYMER and LIME MIX SYSTEMS

- Metering screw feed system for accurately and consistently dispensing dry polymers and lime into a secondary process ideal for water, wastewater and chemical processing applications

- Complete skid mounted system with aging/mixing tanks, pumps and piping

- Built-in hopper capacity of up to 10 cu. ft. (large available)

- Feed rate 0.03 to 200.0 cu. ft. per hour depending on feeder screw size

- Accuracy of within 1.0- 2.0% of volumetric feeder.

- Optional gravimetric feeding with integrated “Loss-In-Weight” system, .25 – 0.5% accuracy.

Standard and optional Features

- Rugged steel frame protected by corrosion resistant finish

- Aging/mixing tanks and progressive cavity pump

- Built-in stainless steel gravity fed hopper

- Concentric helical overwind auger with overwrap or agitator screw

- Trough vibrator to assure high accuracy feeding

- Stainless steel feed screws from 3/8” to 4” diameter

- Water and dust proof NEMA 4X control panel with programmable variable frequency motor controller capable of remote installation

90 VDC, wash down gear motor with programmable SCR Controller in NEMA 4X enclosure (optional)

Options

- Integrated “Loss-In-Weight” Feeder with programmable controller

- Custom auger styles and sizes

- HMI PLC touch screen motor controllers

- Wash down and explosion proof motors

- Wetting cones and conveying eductors

- Vibratory agitators

- Dust collectors

- Base stands and elevated loading platforms

- Feeder and scale are designed to accurately dispense

- Dust Collection

- Storage Bins, Bulk Bag Unloader, Paper Bag Dump Station

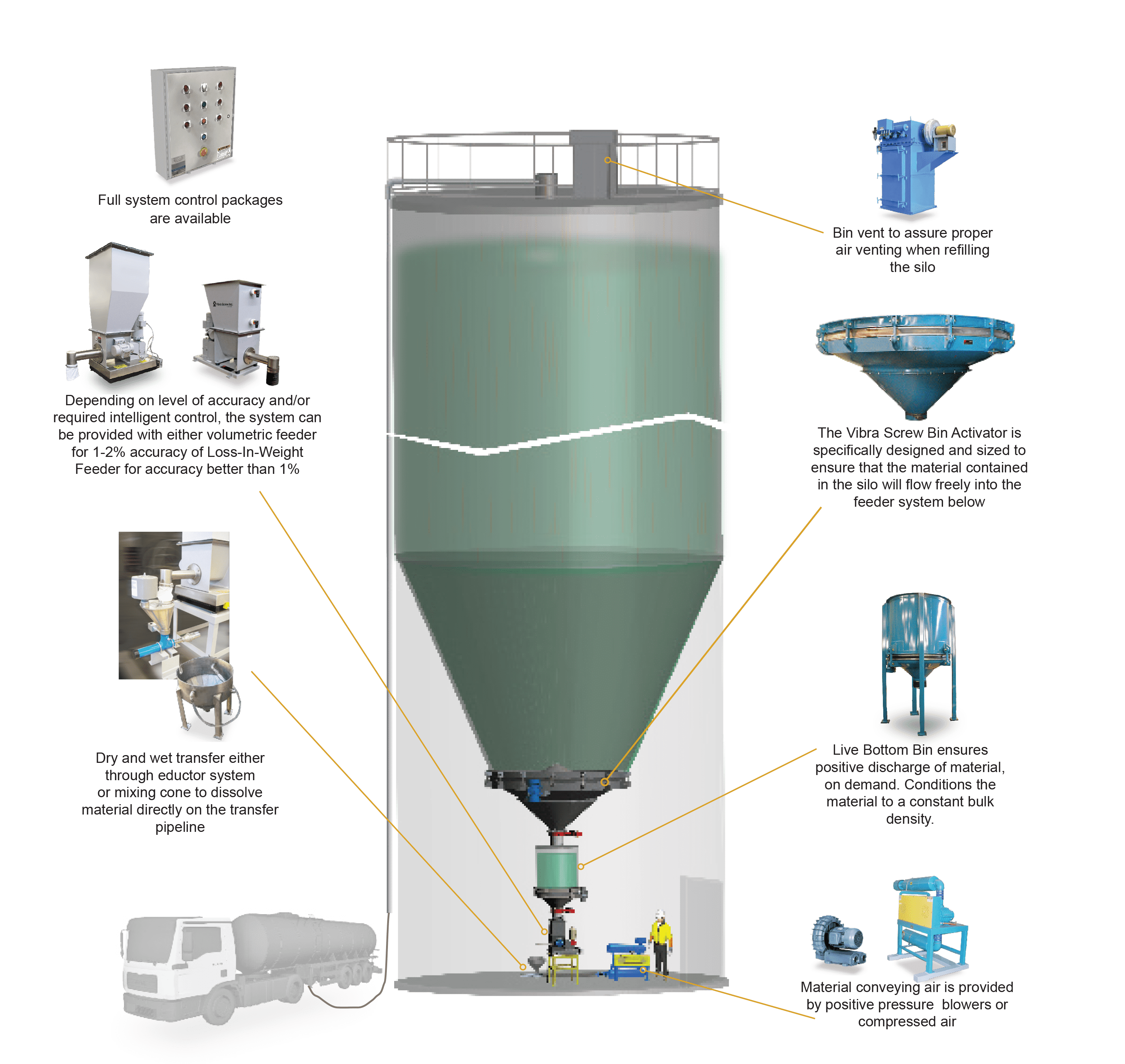

Powder Activated Carbon Systems

Vibra Screw offers sorbent injection systems for adding and mixing of sorbents such as hydrated lime, trona, sodium bicarbonate, or powdered activated carbon (PAC), into the exhaust gas stream.

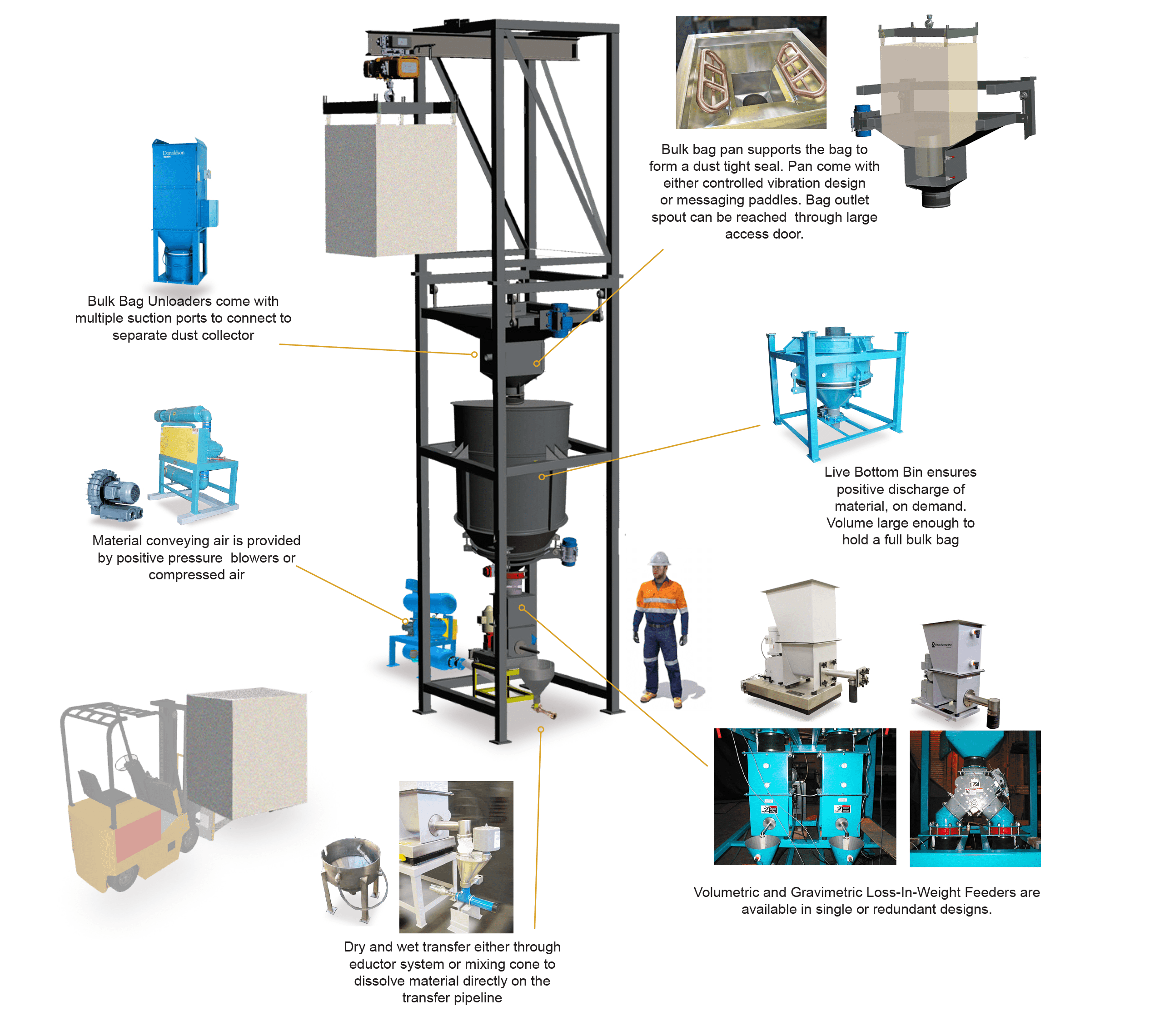

Sorbent injection systems can include the following components, depending on application requirements:

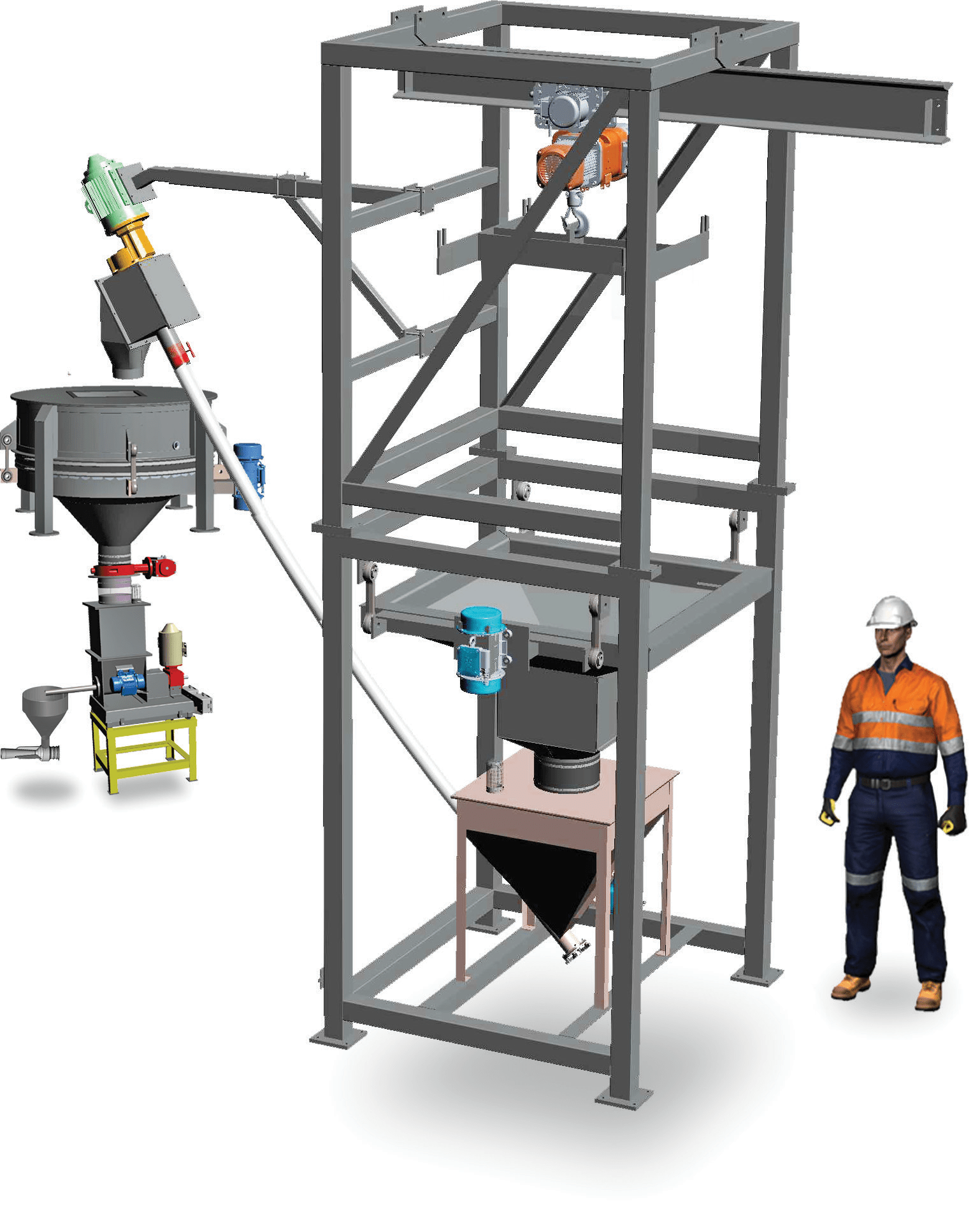

Bulk Bag Unloaders including:

- Bag support hopper to seat and seal bulk bag

- Fork lift adapter or hoist and trolley

- Dust collection system

- Vibrator/gyrator on hopper

- Messaging Paddles (optional)

- Flexible feeders for conveying materials to injection point via automatic refill

- Metered feeders for accurate sorbent feed into gas system including both Volumetric or Gravimetric Loss-In-Weight

- Tandem or redundant system design using two feeders and injection system with single bag unloader

- Integral hopper with level probes (volumetric)

- Optional: Live Bottom surge bin with high/low level probes

- Motor and gear reducer with motor controller mounted in control panel

- Water and dust proof NEMA 4X control panel with programmable variable frequency motor controller

capable of remote installation - 90 VDC, wash down gear motor with programmable SCR Controller in NEMA 4X enclosure (optional)

- Wet/dry slurry injection and gas mixing vessel

- Regenerative or PD blower to produce motive air. Piping by customer

The ability to provide expert solutions to a wide range of industries comes from Vibra Screw’s 65 plus years of developing, designing and manufacturing equipment for the material handling industry. Our team of highly experienced engineers provide industrial solutions designed for safety, reliability and performance.

Being a solution provider in the bulk solids handling industry, our strength comes from R&D, custom design and production capabilities for each individual application.

Powder Activated Carbon Systems

In the process of combustion at high temperatures, various gases are created and released to the atmosphere. These gases can be toxic and harmful to human health. Powdered Activated Carbon (PAC) is an adsorbent engineered to eliminate such toxic gases like dioxins, organic compounds and other chemicals like mercury.

Injecting PAC to the pipeline at the baghouse filter inlet adsorbs these gases. PAC within captured flue gases like dioxins, and heavy metals are captured by the filter bags and prevent the release to the atmosphere.

Bulk Storage Systems

Bulk Bags (FIBC) Unloading Systems