The strong growth of the pet food industry in recent years, which is expected to continue in the foreseeable future, has accelerated investments in the production sites of many companies that sell dog and cat food in highly competitive markets.

The strong growth of the pet food industry in recent years, which is expected to continue in the foreseeable future, has accelerated investments in the production sites of many companies that sell dog and cat food in highly competitive markets.

The Challenge

In 2022, a Missouri, pet food production site asked a global supplier of manufacturing technology and services to design and install a system that would help optimize the efficiency and safety of its material handling processes.

The Solution

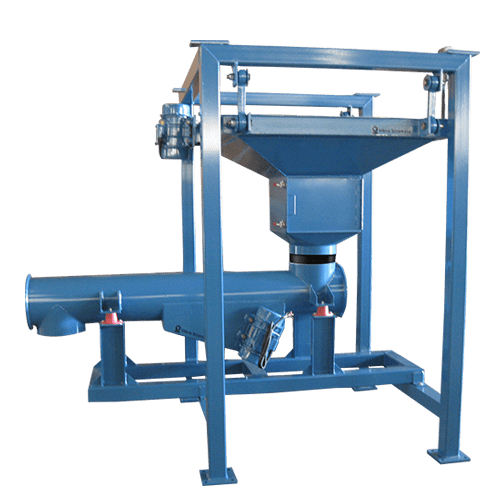

A Vibra Screw Model 2-VHD bulk bag unloader with a system of massage paddles, pneumatic bellows, and vibration was specified. Since its installation, the system has achieved its performance goals and helped the site optimize the efficiency and safety of its pet food materials production operations. Previously, three people were required to manually unload each of six bulk bags a day. Now, with the Vibra Screw bulk bag unloader, only a single operator is required for the same daily volume. Although materials typically flow well into the bulk bag unloader most of the year, Mounted on a heavy-duty steel frame good for capacities up to 4,000 pounds, Vibra Screw bulk bag unloaders make handling of bulk bags and totes practical by providing an easy and safe method to lift, support and discharge materials. The secure connection between the bulk bag unloader and portable bins eliminates dust and spillage associated with other methods of bulk bag handling, and permits controlled, regulated discharge to a variety of feed devices and weight control options.

Unique features of Vibra Screw bulk bag unloaders include a bulk bag support hopper that is designed to seat and seal the bulk bag before it is opened. An operator is not required to reach beneath a suspended bulk bag to open the outlet. In addition to a two-point dust collection system, the Vibra Screw bulk bag unloaders also feature a no-spill design unlike other open frame, paddle support systems.

Also unique to the Vibra Screw bulk bag unloader is a choice off either vibrating discharge system incorporating the same design principles as state-art-of-the-art Vibra Screw Bin Activators, or Bulk Bag Massaging paddles (bar type) pneumatically operated, using two air cylinders. It provides a means to condition the bag to enhance material flow out of the bag. Air operated , air set, filter regulator, solenoid valves operated by two timers for on/off operation thereby assuring complete discharging of materials without the need for repositioning or adjusting bulk bags.

The Result

Operators at the pet food production site in Missouri are pleased with the investment made by the company in a material handling system that helps optimize efficiency and safety. It’s an investment that can contribute to their growth in expanding and competitive pet food markets for years to come.