Can you afford to get caught without a critical part?

You can’t drive your car forever with the same oil, brakes, muffler and tires. Periodically it will need to be serviced. Solids processing equipment is no different. It needs to be properly maintained in order to perform within its design parameters. And, eventually certain parts will need to be replaced. Maintaining a spare parts inventory is often considered a luxury you can’t afford. But stop to consider how much downtown you can afford if a critical part fails. There is no perfect answer but here are some insights into some different types of equipment and parts.

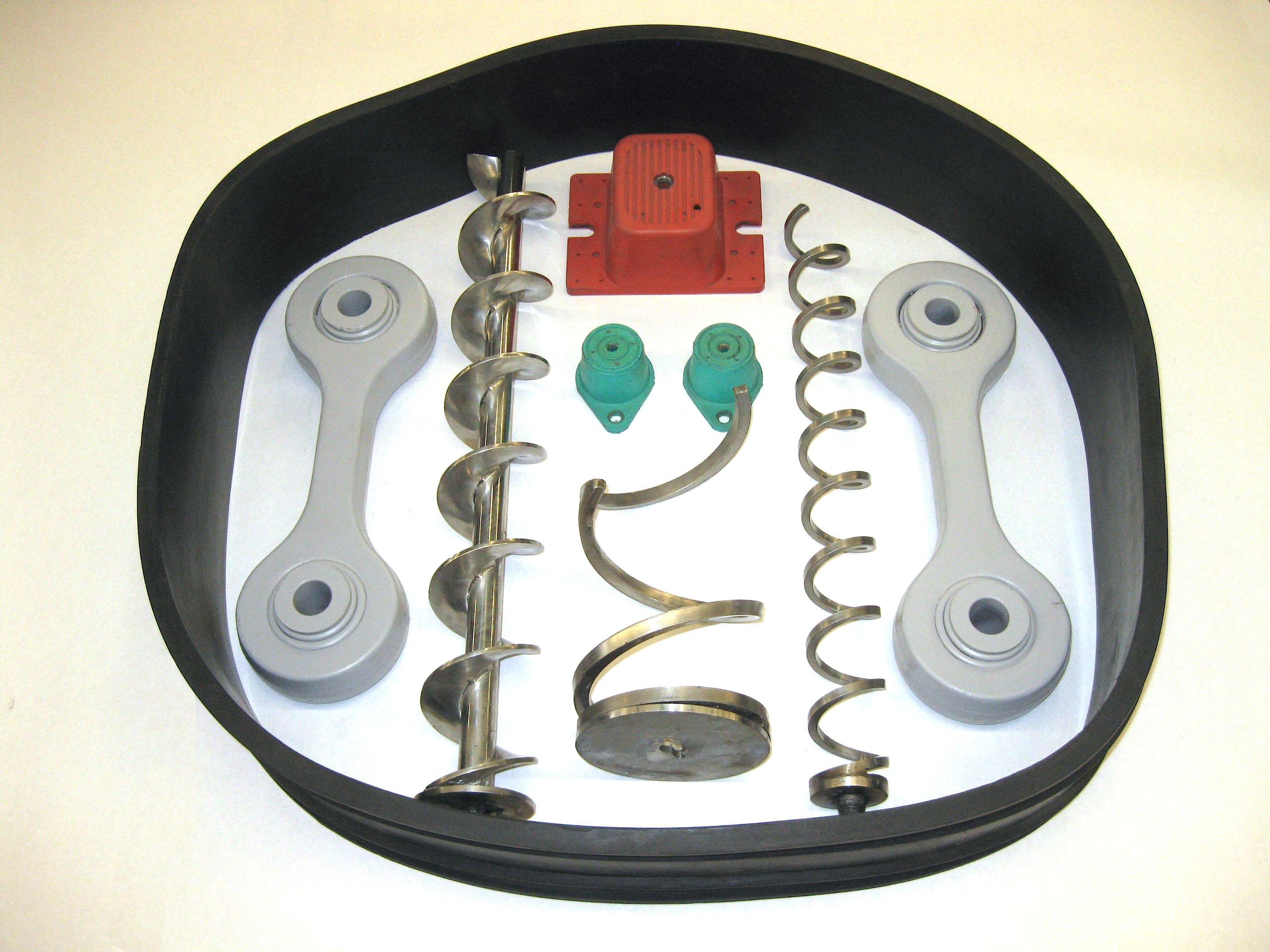

Spare parts for solids processing equipment might include sleeves (elastomer seals), hangers, flight screws, conditioning screws, isolators and wire screws.

Spare parts for solids processing equipment might include sleeves (elastomer seals), hangers, flight screws, conditioning screws, isolators and wire screws.

In the best of conditions, solids processing equipment like vibrating bins, bin activators, vibrating conveyors and screw feeders, are subject to stresses that will, over time, cause critical part failure. Even if the part in question is a standard item and readily available, you need to gauge the consequence of the downtime resulting from ordering, shipping and installing that part. What if that part requires custom manufacturing? How much downtown is too much? At what point should you consider having a replacement in your spare parts inventory. It is a question you should be asking before a part fails.

Bin Activators have two critical parts that will need to be replaced and we recommend you have spares.

- Elastomer seals between the bin and the bin activators

- Isolators for your bin activator hangers

After two years of service these parts should be carefully inspected. This inspection should then be repeated every six months. Obvious signs of degradation are checking and cracking. Also examine your isolators for sag. If signs of fatigue or wear are detected, these parts should be replaced. If you have spare parts on hand, be sure to inspect them carefully before installing them. Elastomer parts in extended storage can be compromised. Nevertheless, the cost of the part vs. the cost of the downtime suggests having spares is a wise decision.

You might think that the Gyrators on vibratory equipment are subject to a high rate of failure due to what is perceived as their high-stress function. The fact is, in continuous use situations, they are subject to very little stress. Gyrators are oil lubricated and with proper maintenance they can last years. Simply conduct the recommended inspections every 1000 hours of operation and change the oil every 6000 hours. Like a well maintained car, you can get years of trouble-free service following a simple maintenance routine. When processing is not continuous and Gyrators are frequently started and stopped, stresses on the Gyrators are increased and these inspections become more important.

There are also parts that are custom engineered and built specifically for the equipment they help operate. For example, most feeder screws are unique to the feeder they are shipped with. If the equipment is operated according to manufacturer’s guidelines, the screw can last longer than the feeder. But in real world situations, screw failure is all too common and when they break, there is no quick fix. Again, you have to weigh the cost of having a spare on hand vs. the downtime you will experience having to order a custom-engineered part.

So…to borrow a tried and true motto, be prepared. Consider what equipment you are operating, how it is being used and your tolerance for downtime. Refer to your manufacturer’s recommended spare parts list. If you have questions consult your equipment manufacturers and get their recommendations to help find the balance between the investment you are able to make in spare parts and the risk you are willing to take. Our experience shows that you should have some spare parts on site. It will pay off some day.