Fumed silica also known as pyrogenic silica because it is produced in a flame pyrolysis of silicon tetrachloride or from quartz sand vaporized in a 3000 °C electric arc. Fumed Silica consists of microscopic droplets of amorphous silica fused into branched, chainlike, three-dimensional secondary particles which then agglomerate into tertiary particles. The resulting powder has an extremely low bulk density 2.5-11.8 lbs/ft3 (40–190 kg/m3) and a primary particle size of 5–50 nm (which is smaller than the average particle from cigarette smoke) and high surface area.

Fumed silica serves as a universal thickening agent and an anticaking agent (free-flow agent) in powders. It is used in cosmetics for its light-diffusing properties. It is used as a light abrasive, in products like toothpaste. Other uses include filler in silicone elastomer and viscosity adjustment in paints, coatings, printing inks, adhesives and unsaturated polyester resins.

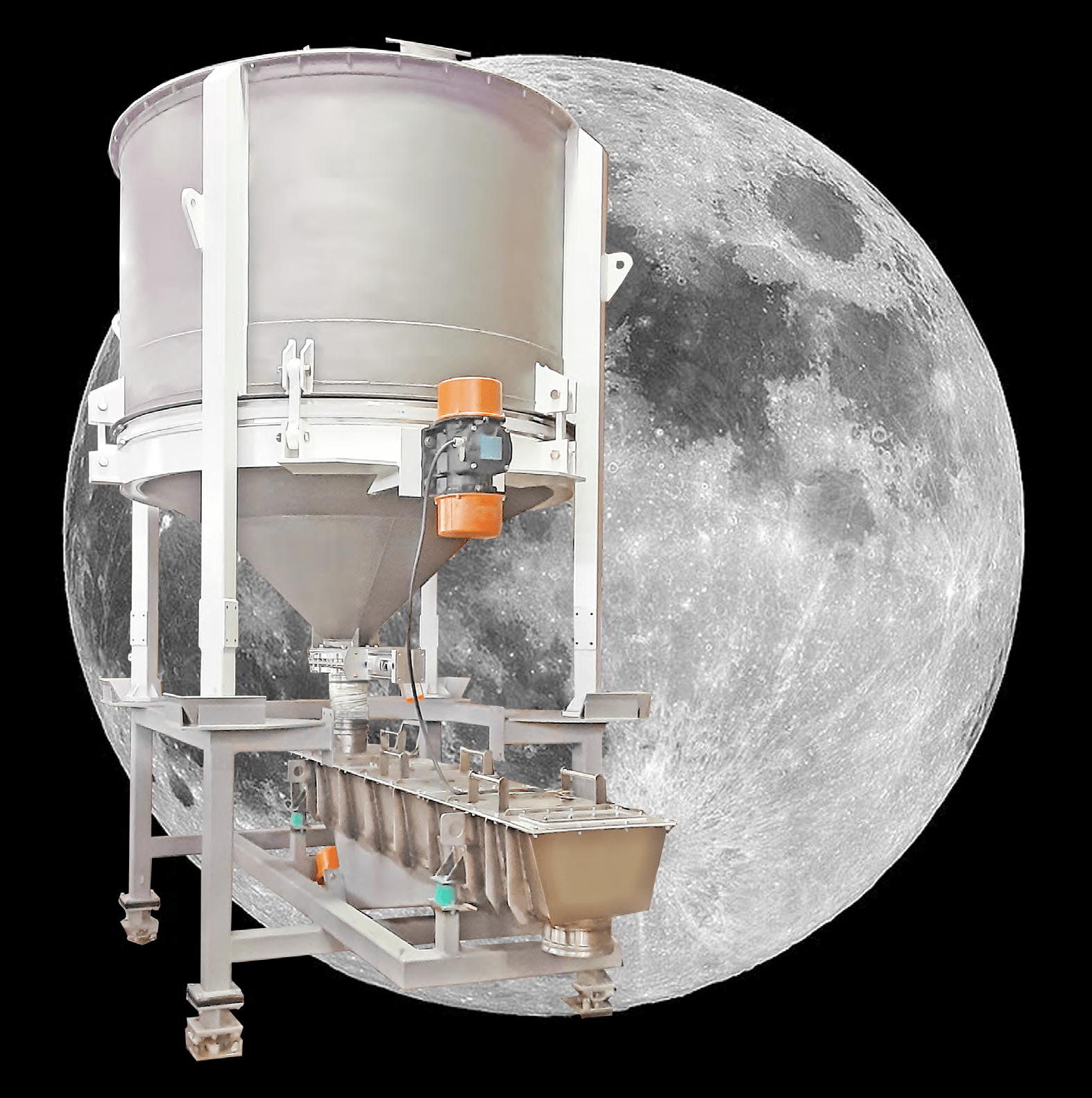

Because of its very low bulk density and small particle size, fumed silica is extremely difficult material to accurately feed into process. For decades Vibra Screw has been metering fumed silica with our controlled vibration screw feeders. The photo shows a Vibra Screw Live Bottom Bin and 2” VersiFeeder volumetric screw feeder. Both work using controlled vibration to de-aerate the material to a constant bulk density and assure the flights of the feed screw are completely filled with material. Typical feed accuracy of 1-2% can be obtained.

For decades Vibra Screw has supplied material handling equipment to the aerospace industry for the space shuttle booster engine and military rockets. Once again we had the opportunity to develop a high accuracy batching system to handle extremely explosive oxidizer powder used as one of the ingredients in making solid rocket fuel. System is comprised of a portable Vibra Screw 200 ft3 Live Bottom Bin and Vibratory Feeder Loss-In-Weight batch system.

For decades Vibra Screw has supplied material handling equipment to the aerospace industry for the space shuttle booster engine and military rockets. Once again we had the opportunity to develop a high accuracy batching system to handle extremely explosive oxidizer powder used as one of the ingredients in making solid rocket fuel. System is comprised of a portable Vibra Screw 200 ft3 Live Bottom Bin and Vibratory Feeder Loss-In-Weight batch system.