OMYA lnc., Florence, Vermont Major manufacturer of calcium carbonate used mainly in the plactics, paint, and paper industries as a filler, extender and coating.

The Verpol plant of OMYA Inc. is the, most modern plant of its kind in the world. It processes

both crushed and finely ground calcium carbonate through its completely computerized operation.

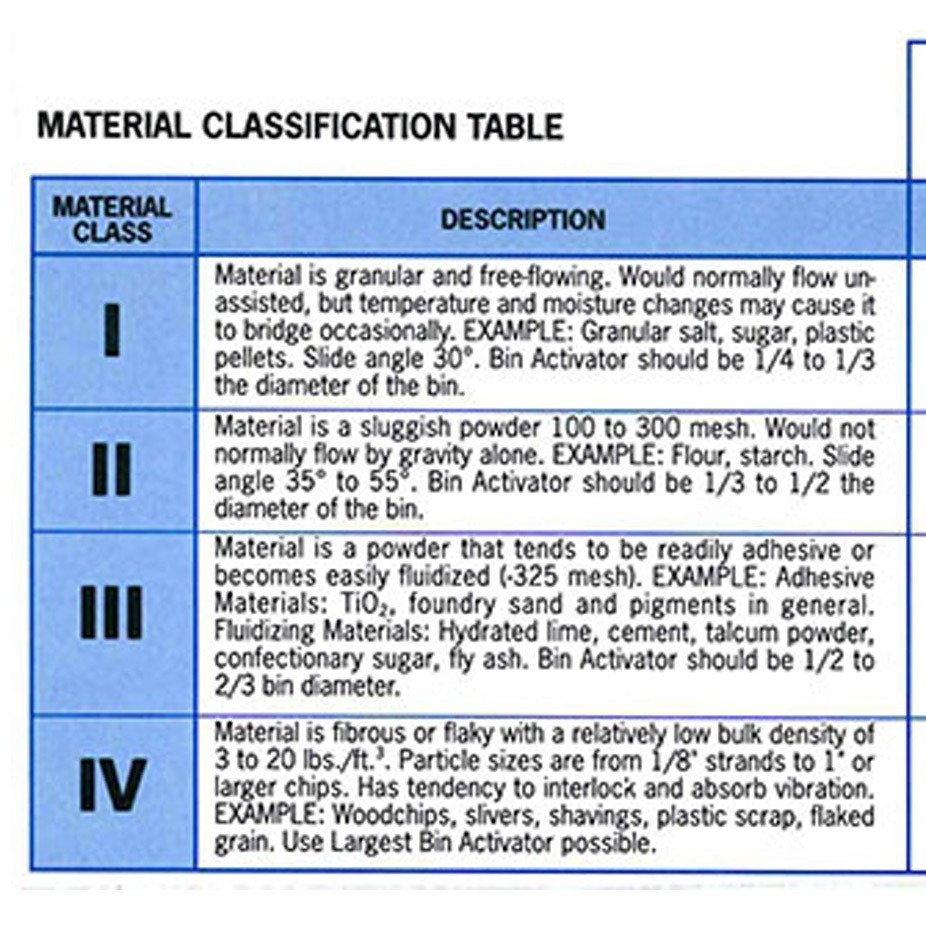

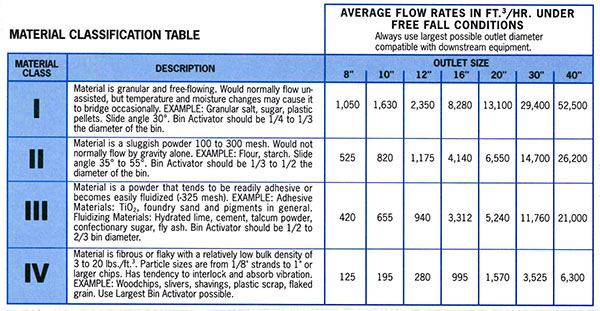

Bulk densities of the materials range from 25 to 70 Ibs. per cu. ft. To meet process and excess

storage requirements, the company has 27 bins ranging from 8 ft. to 26 ft. in diameter, of both concrete and steel construction. The bins are filled either pneumatically or by belt conveyor. Some of the bins are discharged through rotary valves to belt feeders or pan feeders, and some to bagging machines filling 50 lb. bags. Discharge rate varies from 4 tons per hour up to 40, depending on the stage of the process. However, calcium carbonate, especially the finely ground product, can be difficult to discharge from storage because it tends to bridge and clog.

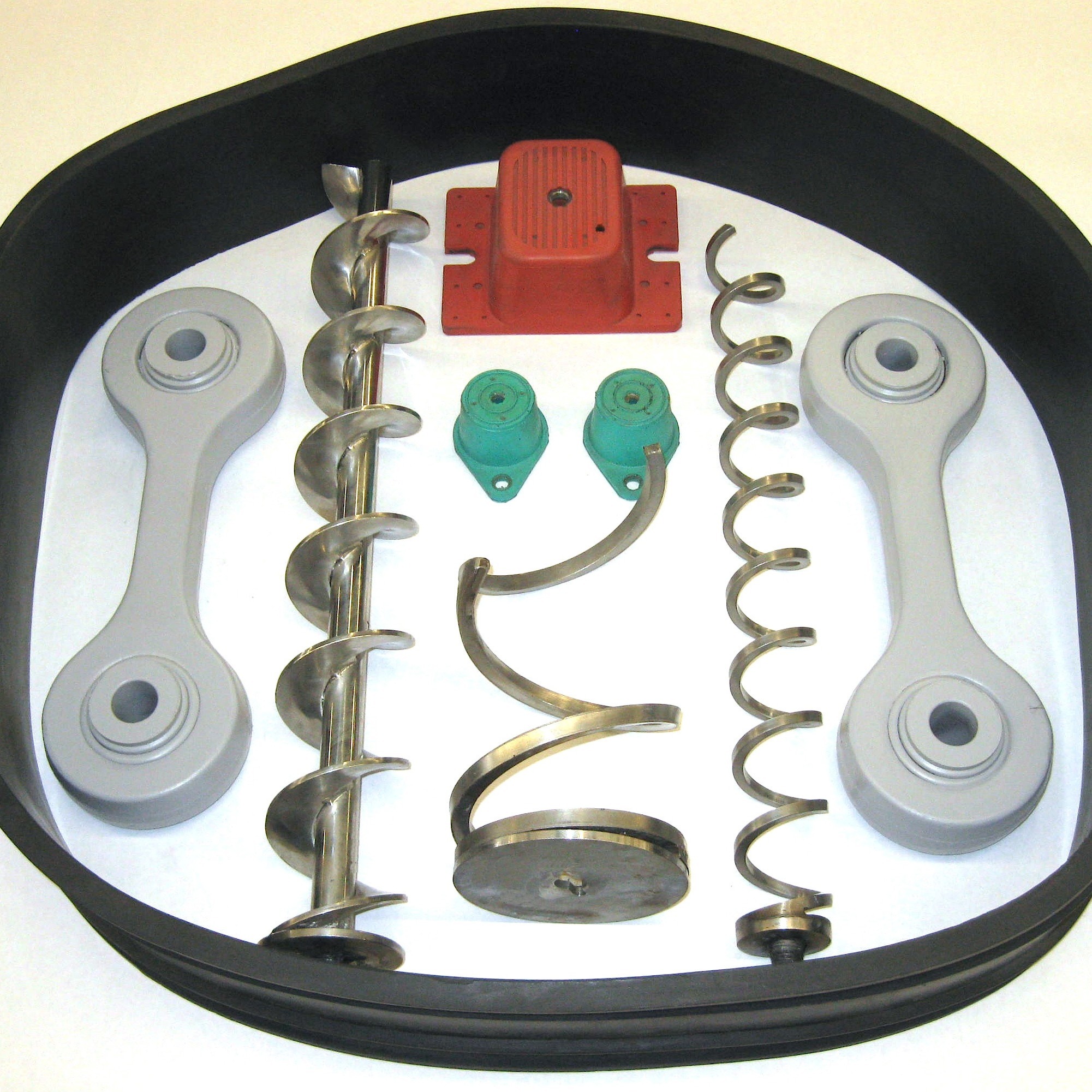

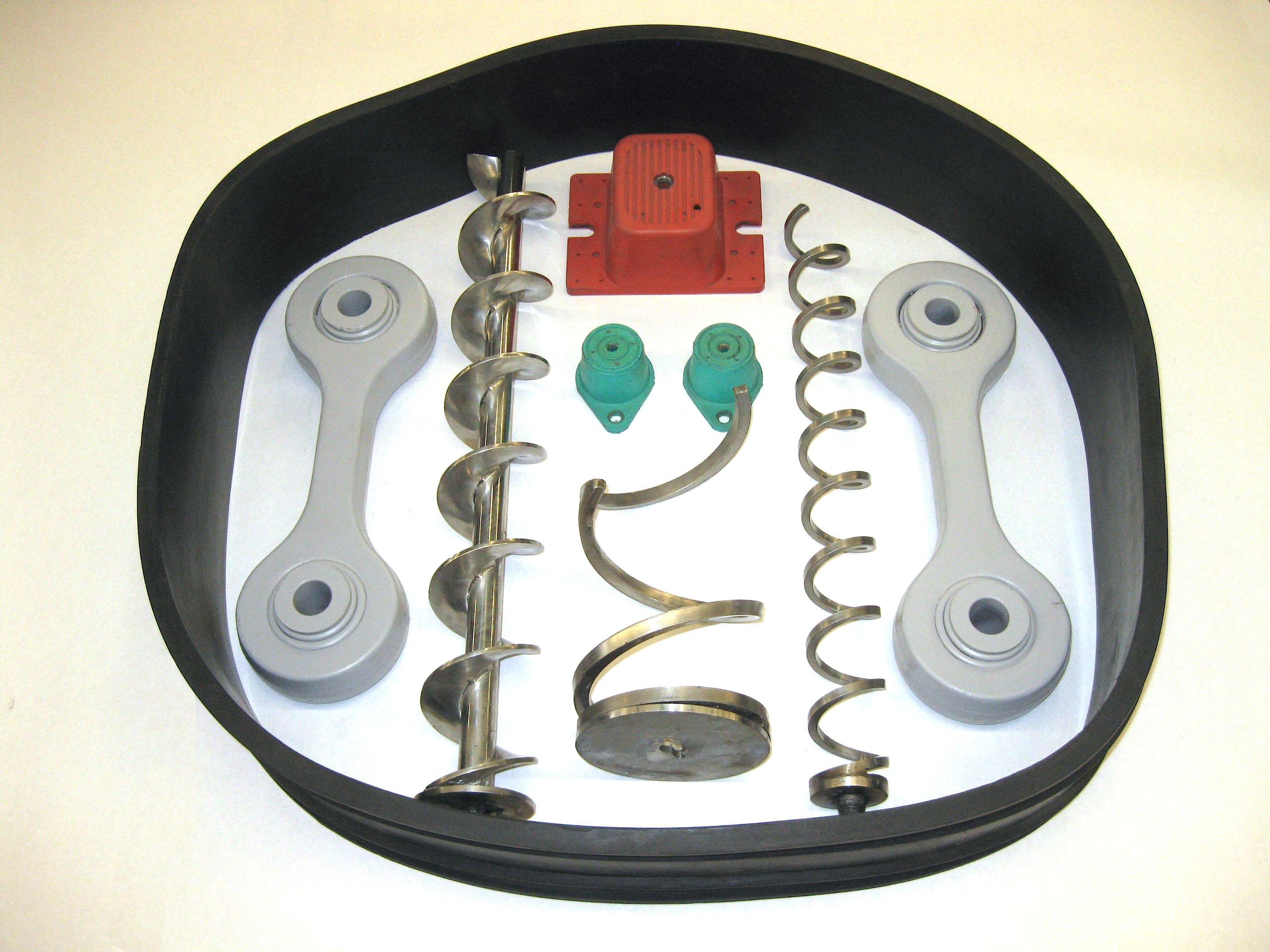

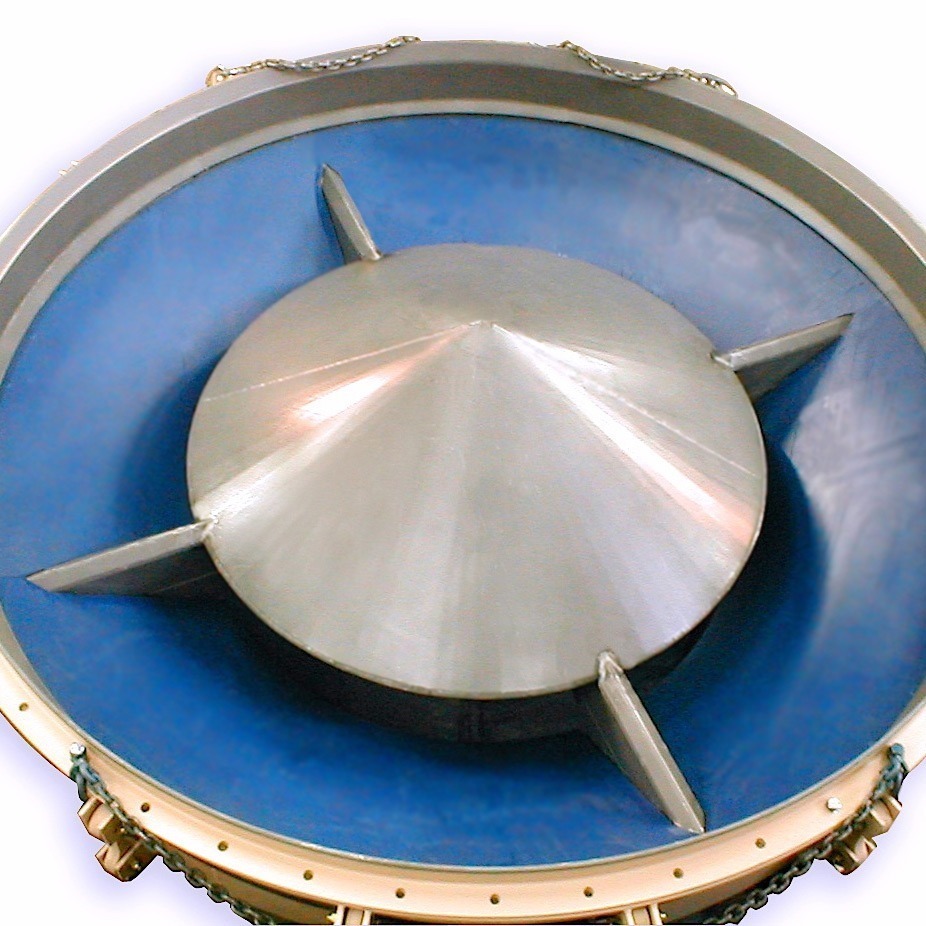

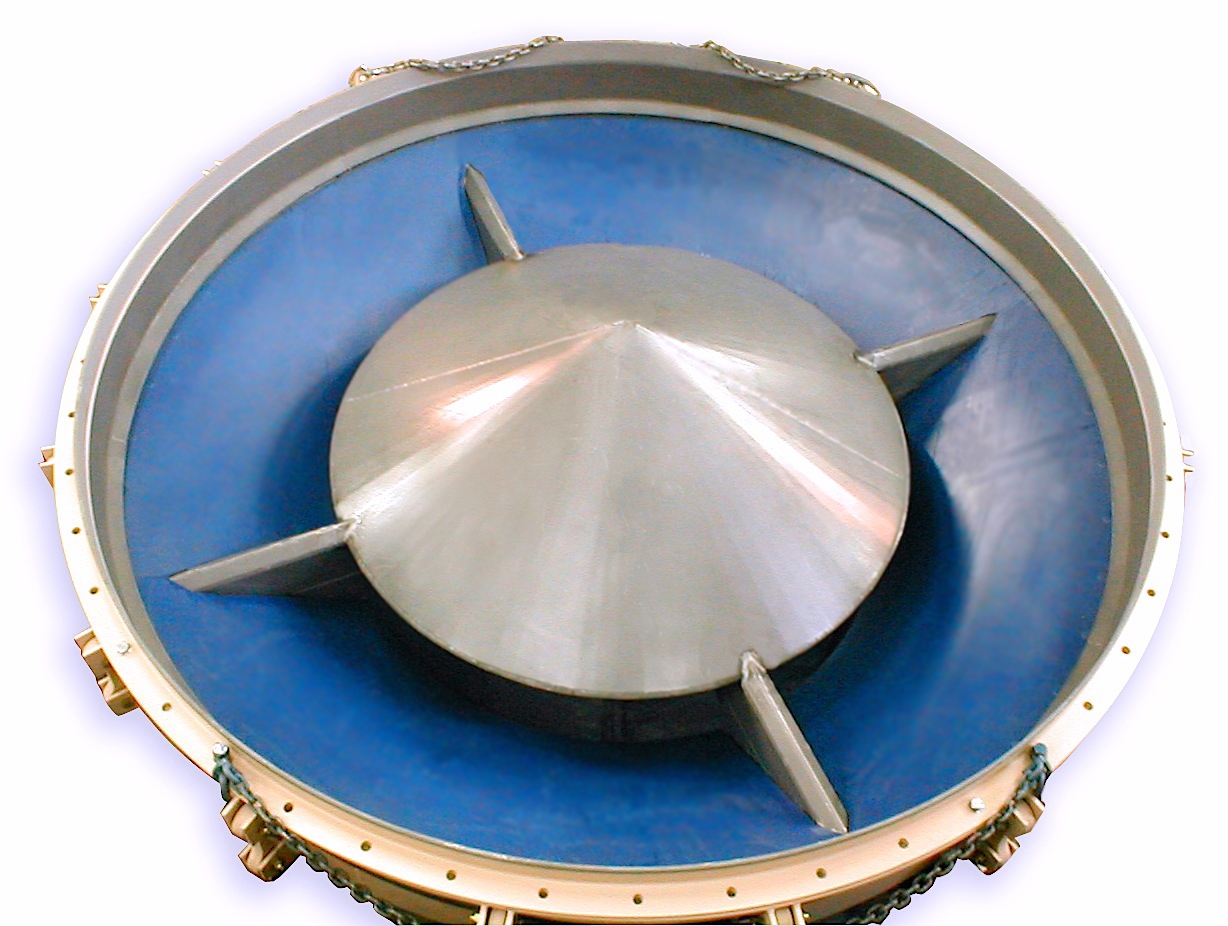

27 Vibra Screw Bin Activators of 3 different diameters (4 ft., 6 ft., and -12 ft.), carbon steel construction, most of which have an epoxy coated interior.

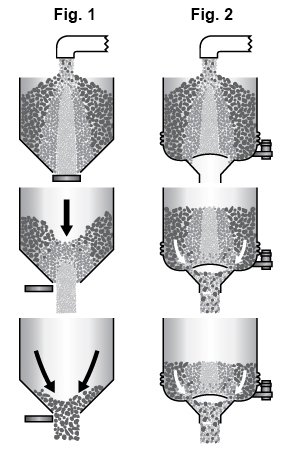

To assure reliable flow of material in its computerized operation, where such reliability is critical, the company decided to install Vibra Screw Bin Activators under all its storage bins. This was possible because the Bin Activators work equally well on both concrete and steel bins. Flexibly mounted to the bottom of the bin, the Bin Activator, but not the bin, is subjected to controlled vibration. An integral baffle located just above the discharge outlet directs vibrations high up into the bin, keeping the material free flowing. An important factor in the handling of calcium carbonate, this action rids the material of entrained air, conditioning it to a uniform bulk density, which helps speed conveying and bagging operations.

OMYA Inc. relies on its Bin Activators to help it produce an uninterrupted flow of high quality product In the words of a company official, “It would be difficult to operate the plant without our Bin Activators.”

Picture what happens when you pour a mixture of stone and sand on the ground. A rough cone forms, with stones mainly around the outside and sand mainly in the center. The stones tend to roll down the surface of the cone as it is formed, while the sand sifts down closer to the center. Segregation has taken place.

Picture what happens when you pour a mixture of stone and sand on the ground. A rough cone forms, with stones mainly around the outside and sand mainly in the center. The stones tend to roll down the surface of the cone as it is formed, while the sand sifts down closer to the center. Segregation has taken place. With Bin Activators, larger quantities can be bulk stored because the risk of segregation no longer limits capacity. Management gains more flexibility in plant design for example with fewer bins and conveyors required. That can lead to improved production and important cost savings.

With Bin Activators, larger quantities can be bulk stored because the risk of segregation no longer limits capacity. Management gains more flexibility in plant design for example with fewer bins and conveyors required. That can lead to improved production and important cost savings.