Phone: 973-256-7410 Email: info@vibrascrew.com

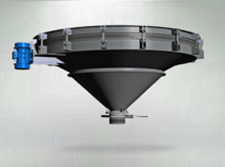

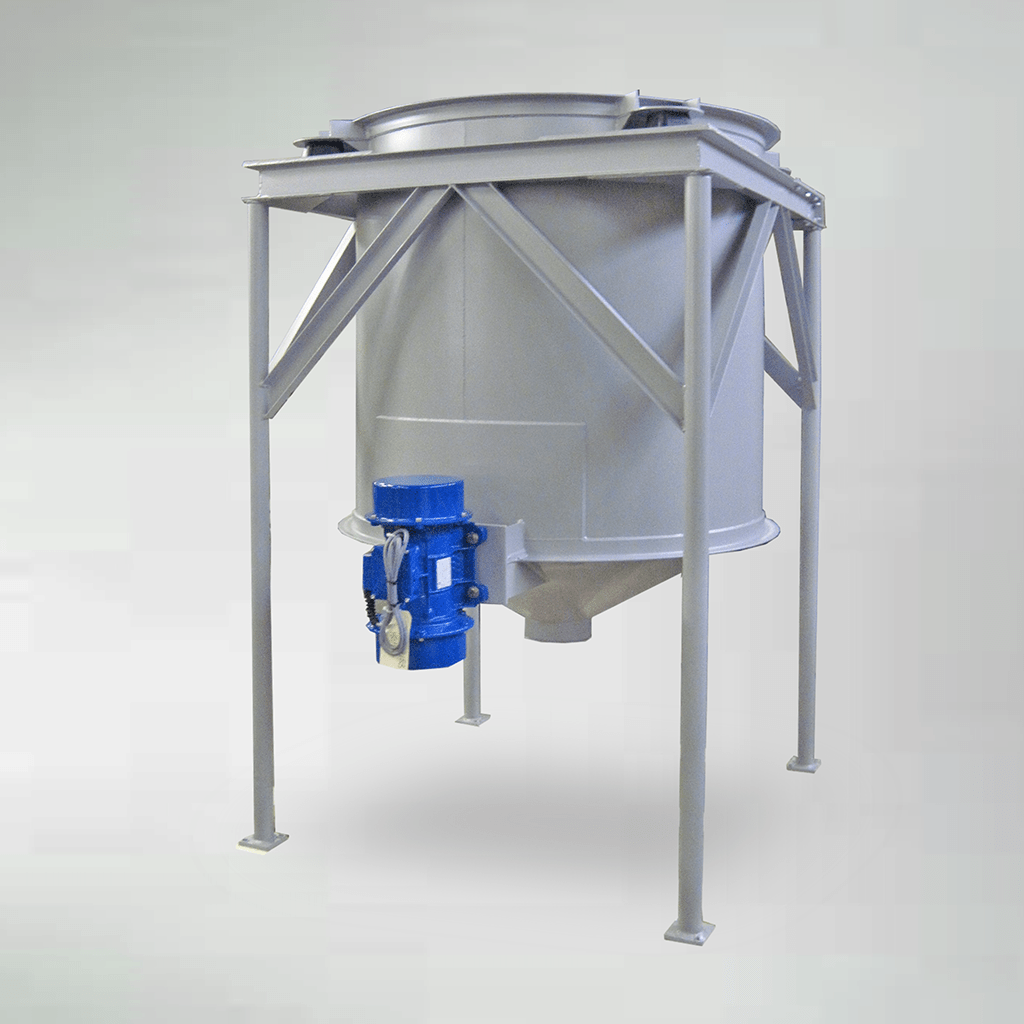

Developed by Vibra Screw Inc. in 1959, the Bin Activator & Bin Discharger have remained the best solution to bin flow problems. They eliminate bridging and rat holing, reduce particle segregation and promote mass flow.

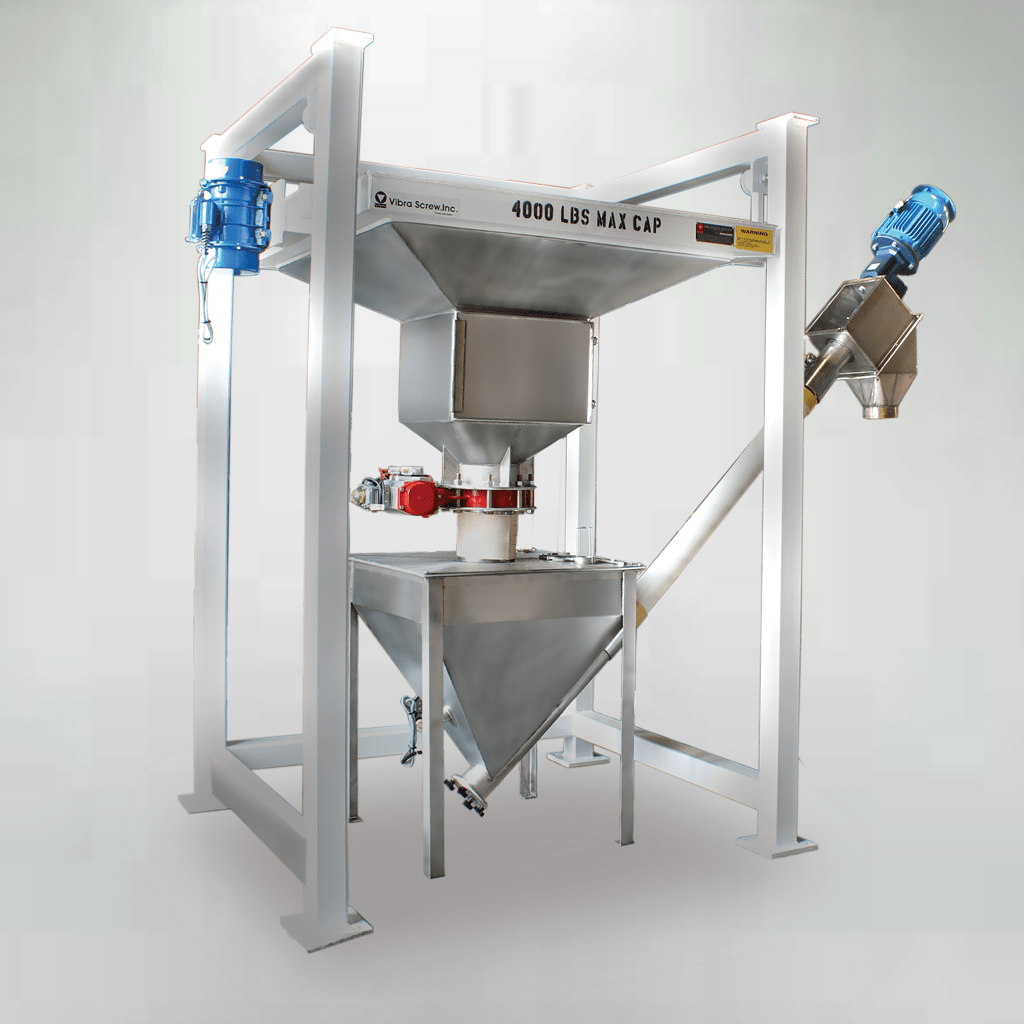

The Vibra Screw Continuous Or Batch Loss In Weight / Gain-In-Weight systems provide unparalleled versatility and accuracy in handling a broad range of feeding requirements.

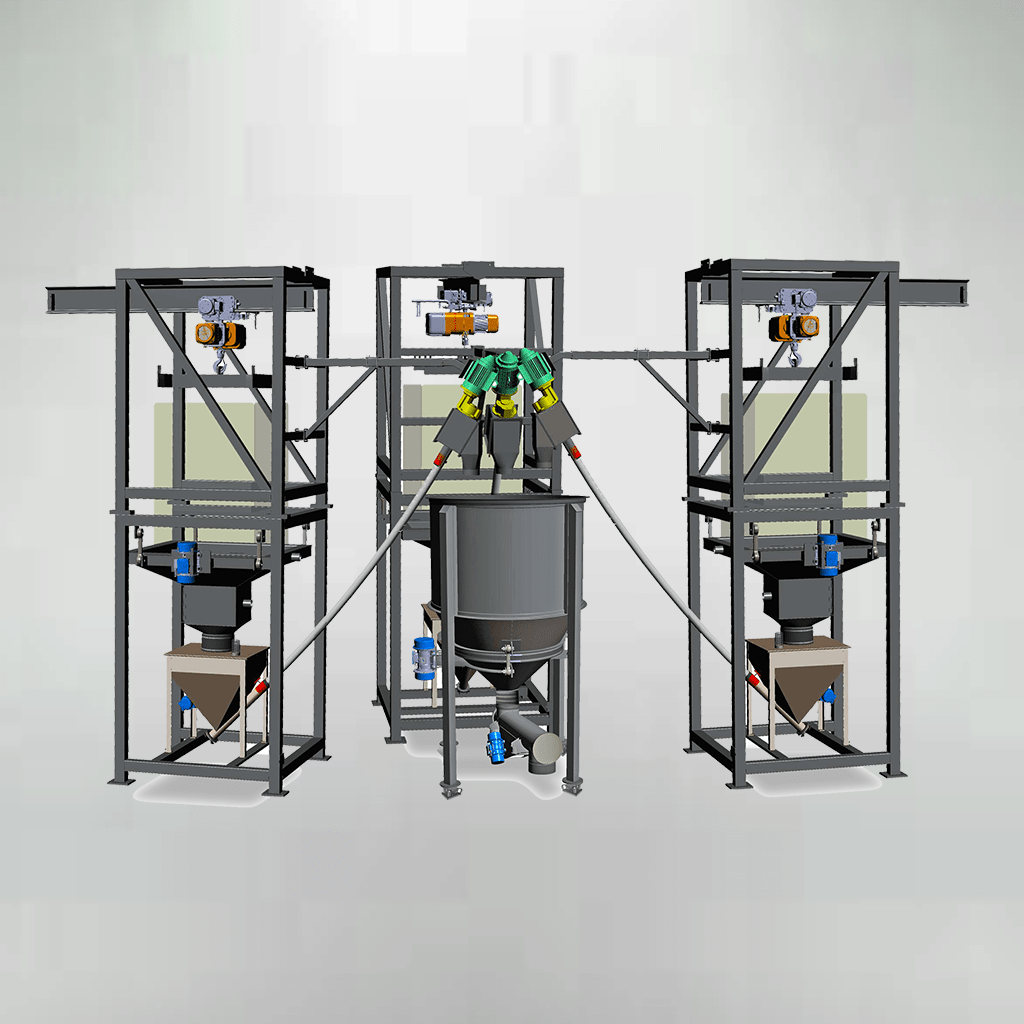

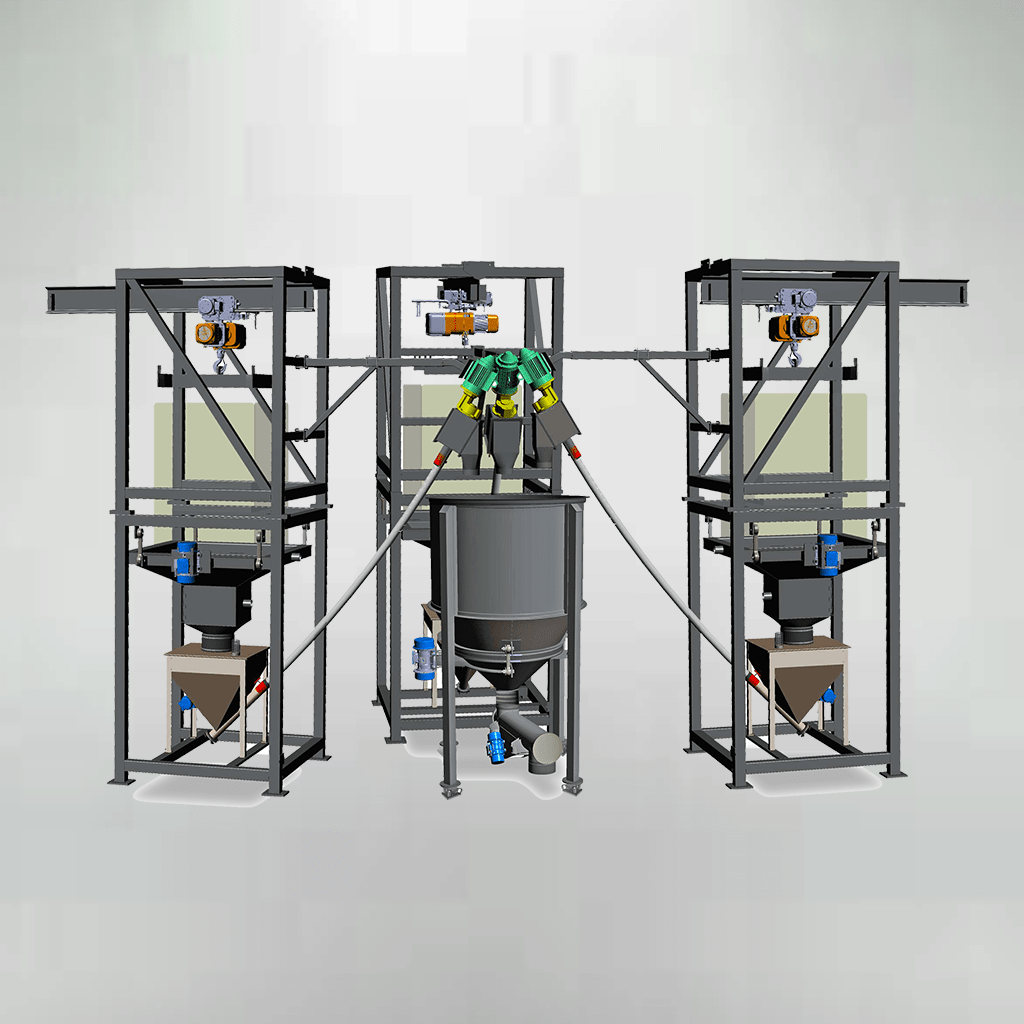

The Vibra Screw Bulk Bag Unloader provides a safe, dust-free way to handle and discharge bulk Bags. Models for hoist or fork truck loading and a wide range of options and accessories offered.

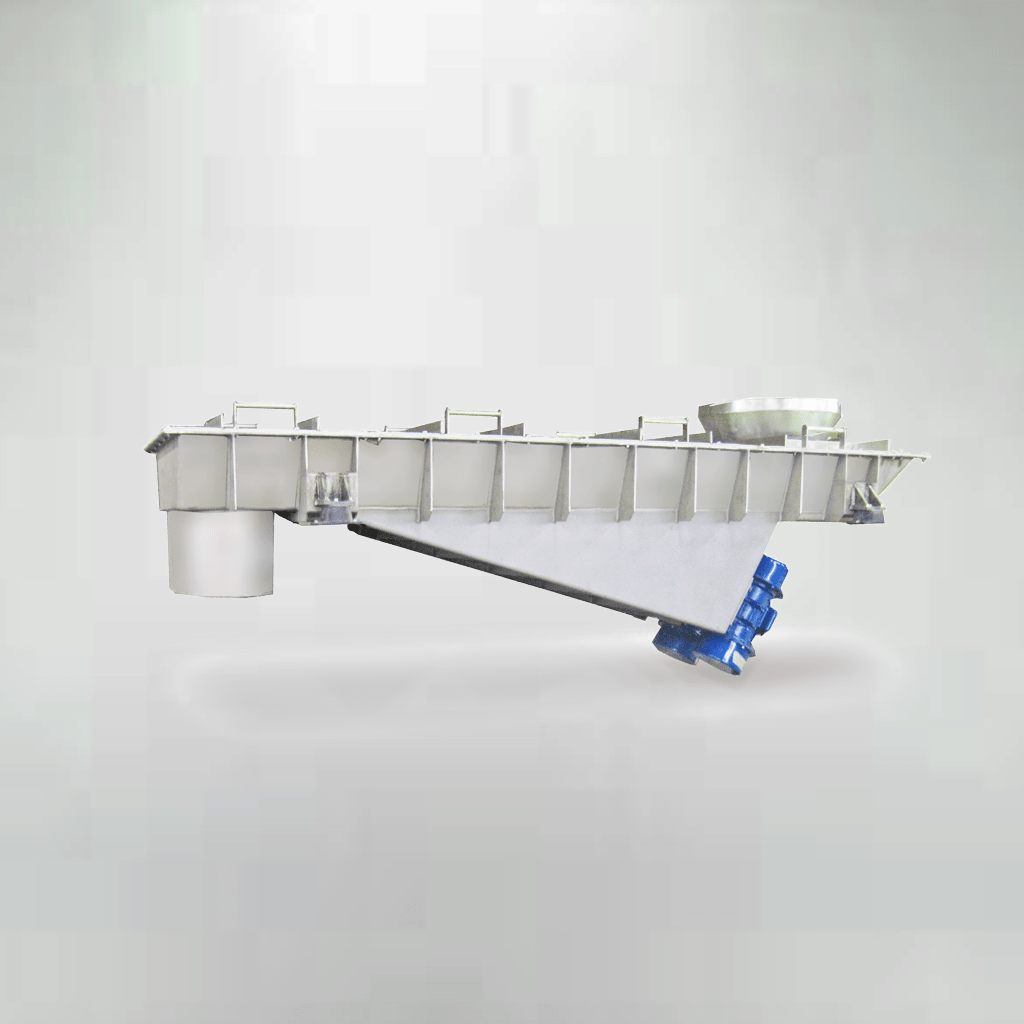

Vibra Screw’s line of Electromechanical pan or tube feeders offer a simple, economical and maintenance free way to convey nearly any material.

Vibra Screw Bulk Bag Fillers insure fast, dust free and precise filling of Bulk Bags. Available in fill by weight or volume models.

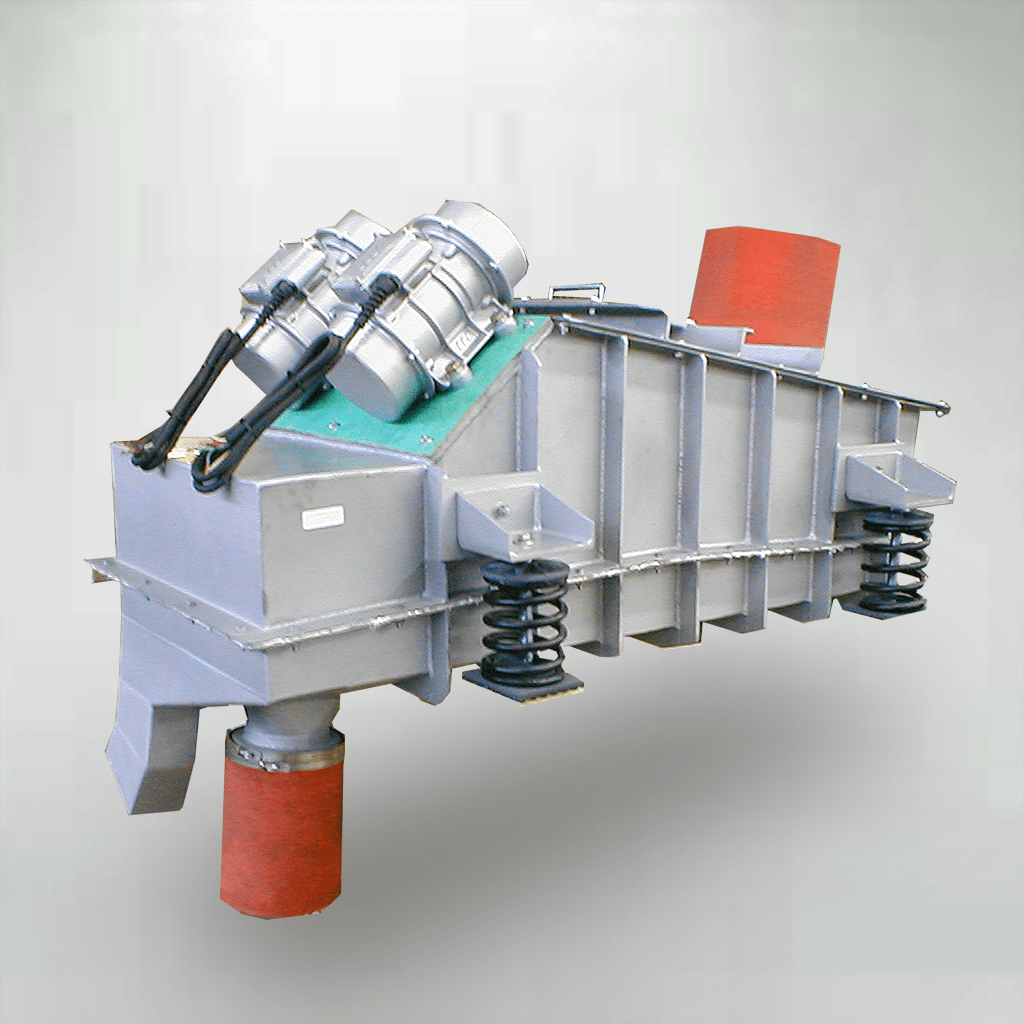

The VSB series of linear vibrating screens can be used for coarse scalping, or dewatering. Units can be modified to suit your special requirements such as high temperature or multiple screen applications.

Vibra Screw Live Bottom Bins are integral Bin Activator / Silo systems available in sizes between 3 ft3 and 1200 ft3 (0.084 m3 to 33.9m3).

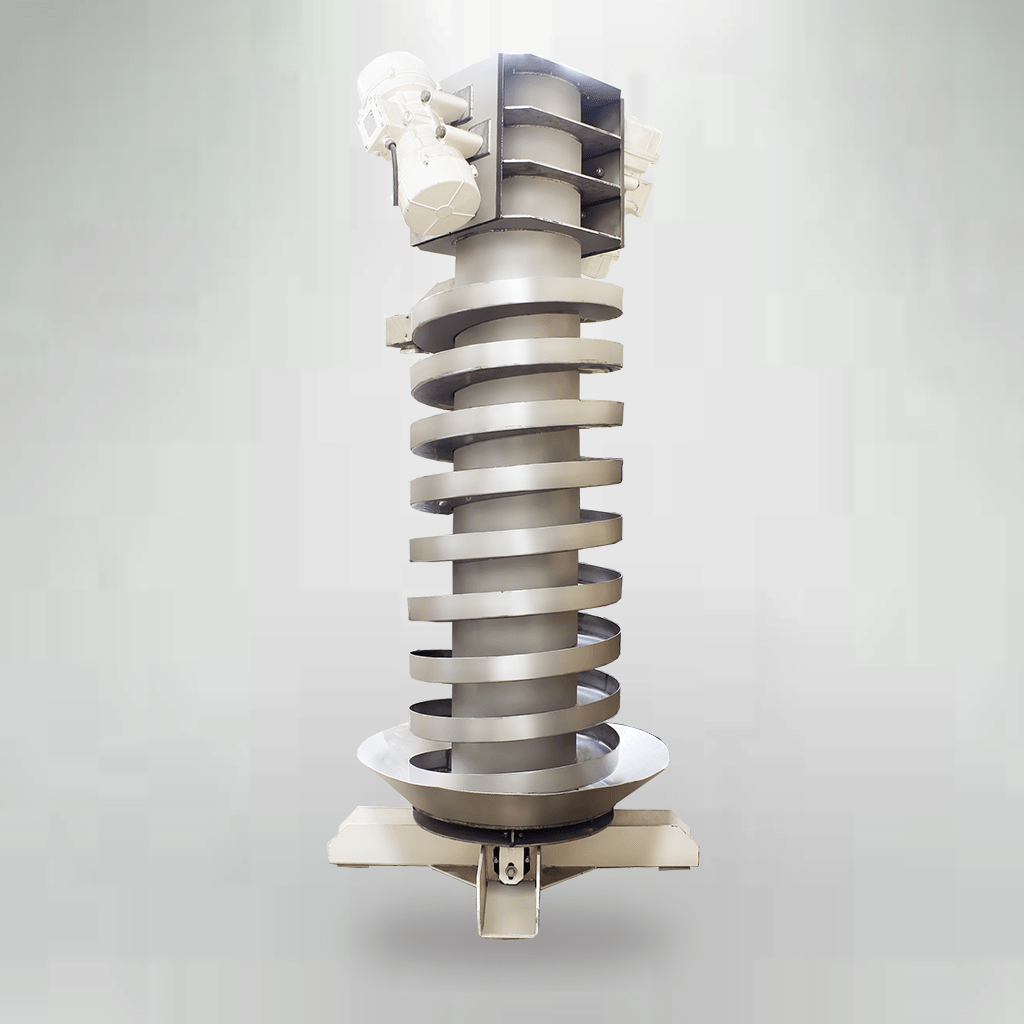

Vibra Screw’s line of Electromechanical Spiral Conveyors is designed to lift material up to 25 ft within a minimal footprint.

Vibra Screw Live Bins are self supported vibrating bins, ideal for sanitary applications. Offered in sizes up to 100 ft3 (2.83 m3).

Using a unique combination of a rotating paddles and material fluidization the Vibra Blender permits dry solids to blend with the ease of liquids.

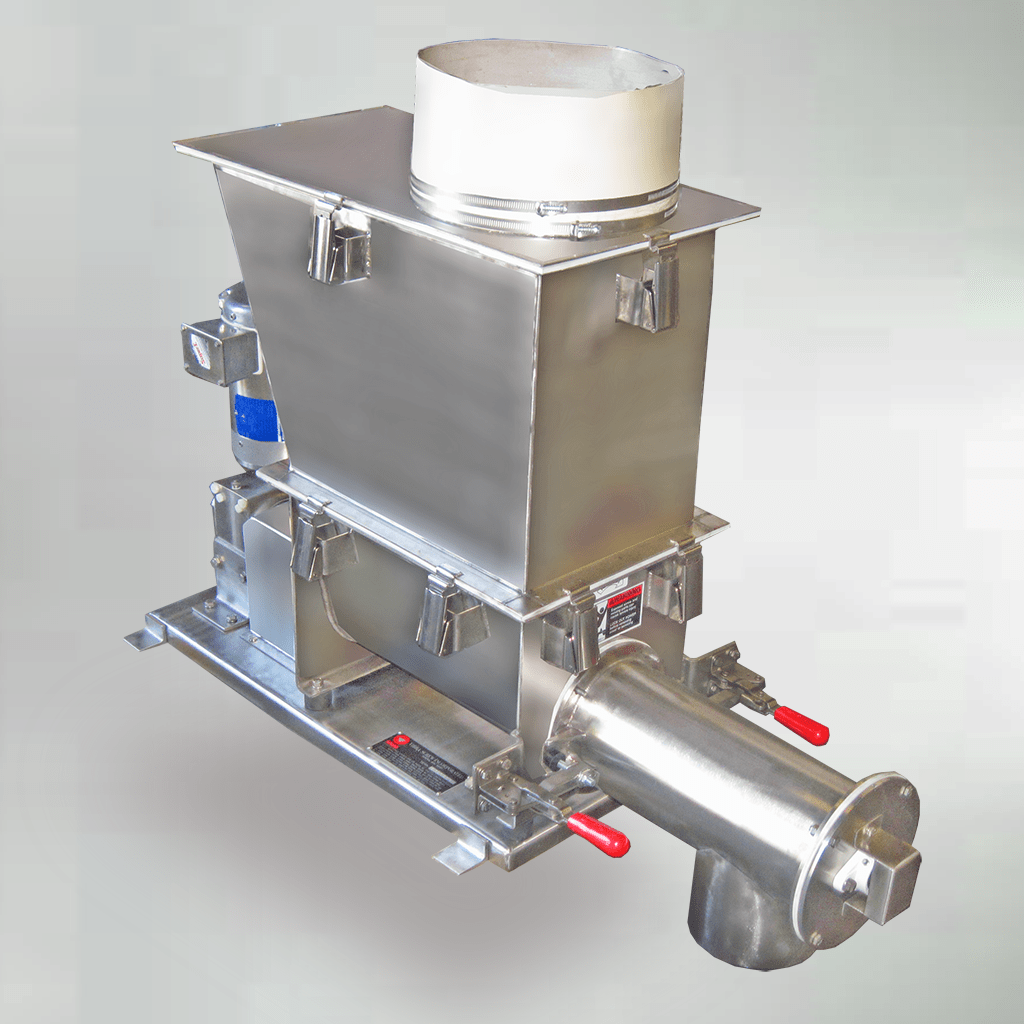

The Vibra Screw VersiFeeder features a modular design enabling a single unit to adapt to the broadest range of feeding applications.

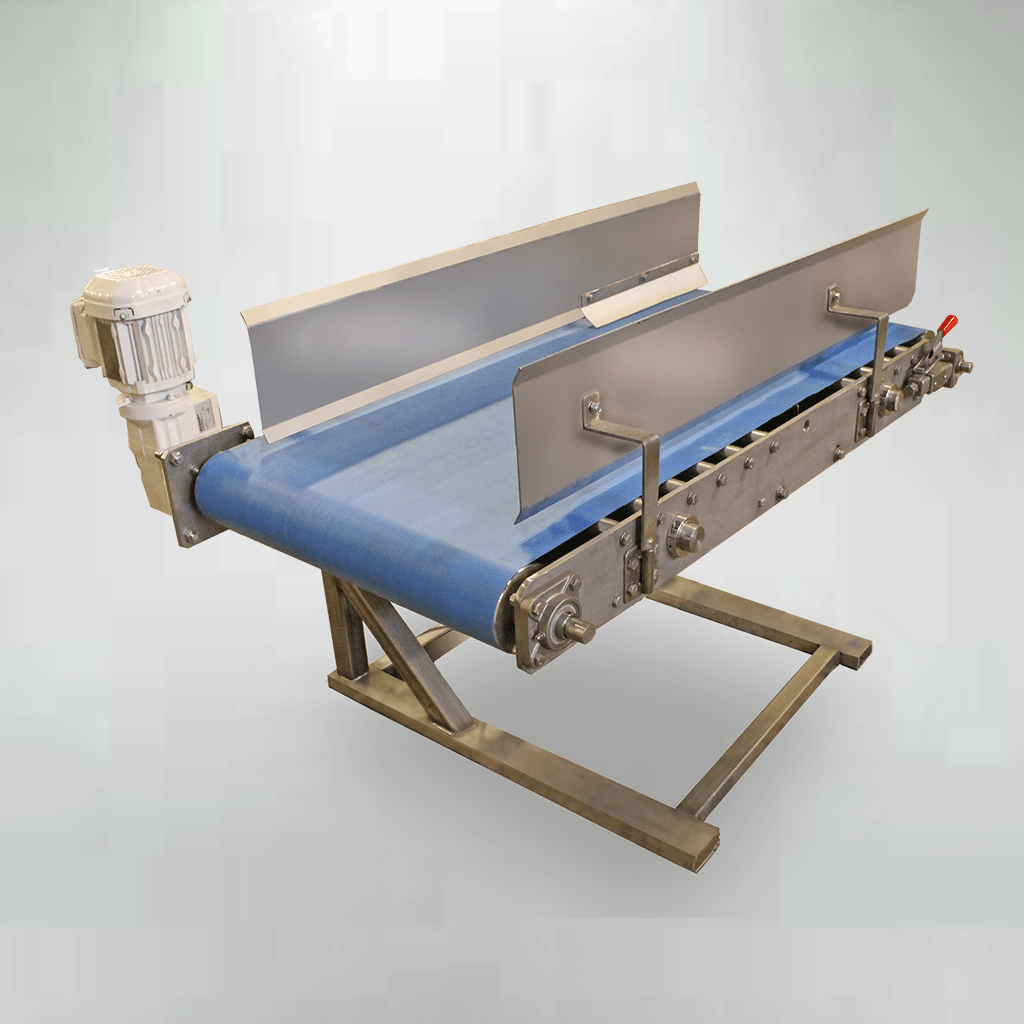

The Vibra Screw Weight totaler Belt Feeder provides accurate feeding and batching for a variety of materials.

The Vibra Screw AccuFeed Screw Feeder is a low cost/quick delivery polyethylene feeder.

Flexible Screw Conveyors offer a low cost and versatile method to elevate and convey materials.

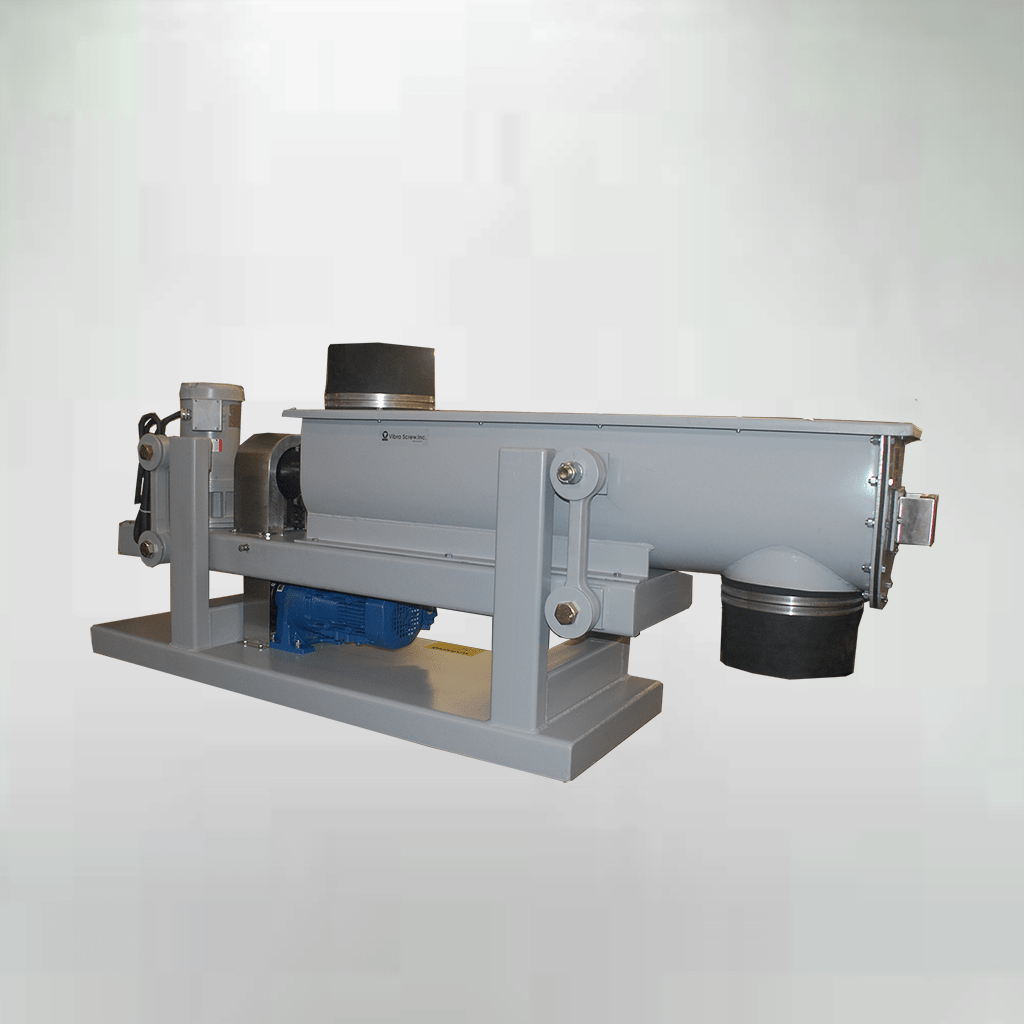

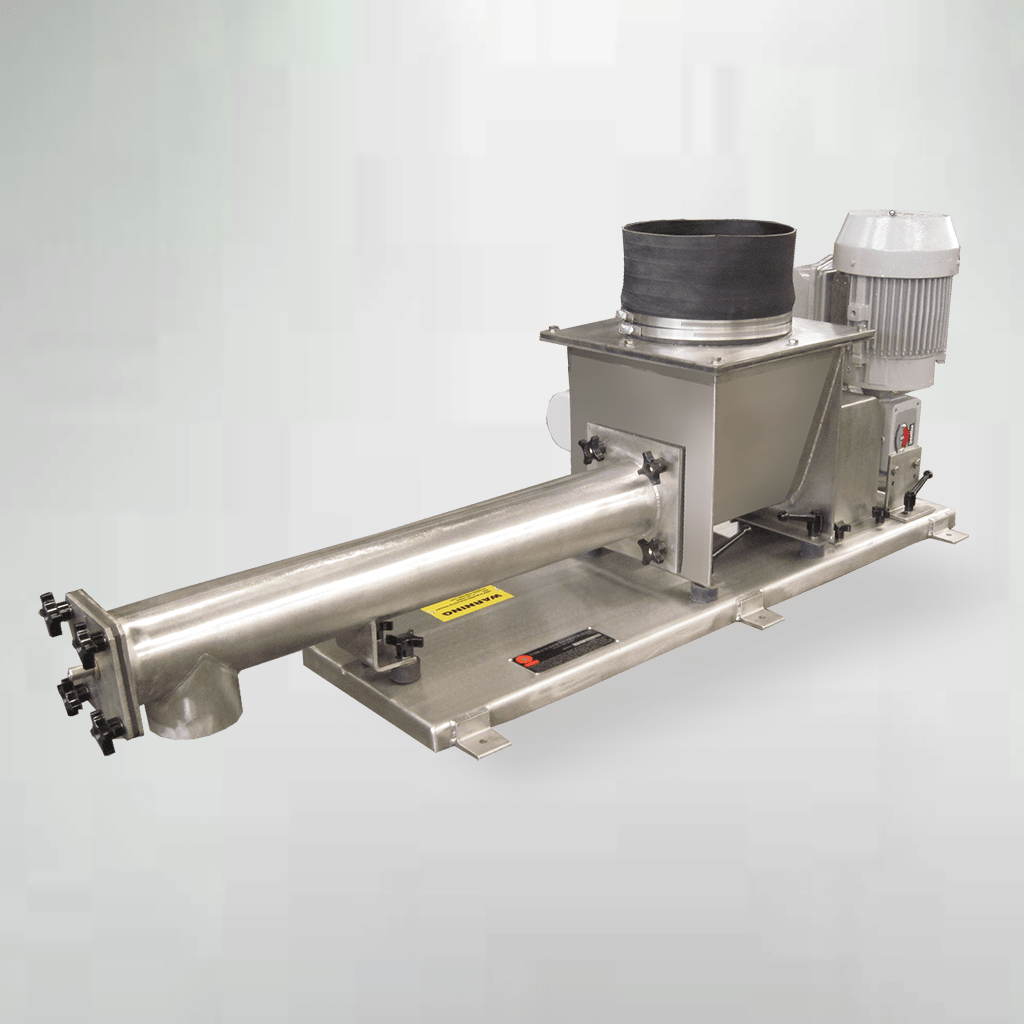

Heavy Duty Screw Feeders are ruggedly constructed for twenty four hours seven days a week operation high rate feeding.

Our innovative and technical experience in the waste water and flue gas / smoke treatment

From mass flow to precision weighing Vibra Screw equipment has been designed specifically to be combined for the most cost effective system for your application.

The Vibra Screw Paper Bag Dump Station is a cutting-edge solution designed to optimize the handling and processing of bulk materials contained within paper bags.

Our offices are temporarily closed. Emails are being monitored by essential employees from home. Please send all inquiries to info@vibrascrew.com.