Vibra Screw Inc has developed a new Bin Activator hanger that provides up to ten times the dynamic load bearing capacity of all previous designs. It prevents nearly all overload issues that can arise in high volume bins with dense or fluidized material, or where pneumatic filling creates higher than normal bin pressures. Costly repairs and production downtime are eliminated.

Vibra Screw Inc has developed a new Bin Activator hanger that provides up to ten times the dynamic load bearing capacity of all previous designs. It prevents nearly all overload issues that can arise in high volume bins with dense or fluidized material, or where pneumatic filling creates higher than normal bin pressures. Costly repairs and production downtime are eliminated.

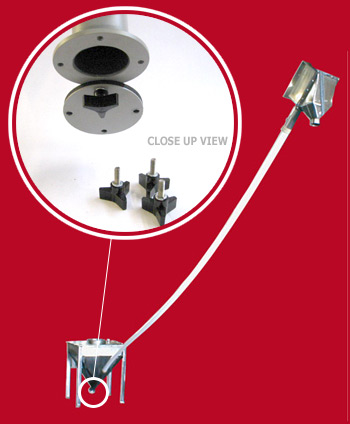

High bin loads can cause rubber isolator bushings in standard hangers to over compress leading to additional vibration transmission to the bin structure and sagging that can create leakage of material from the Activator main seal. The new cable hanger eliminates the rubber isolator while maintaining nearly

Alexco Environmental offered an onsite solution including a 75-ton silo and feed system to feed hydrated lime to treat 200 to 800 gallons per minute of influent. Alexco contacted Vibra Screw Inc. of Totowa, New Jersey, for expertise on equipment for handling bulk powders to see what was needed and what could be shipped within a week. The company offered a volumetric screw feeder with variable speed drive and a controller with 4-20 mA remote speed input, which would allow the lime feed to automatically adjust to the changing pH of the influent. The higher the acidity, the more lime was continuously fed. The system would also treat the heavy metals

Alexco Environmental offered an onsite solution including a 75-ton silo and feed system to feed hydrated lime to treat 200 to 800 gallons per minute of influent. Alexco contacted Vibra Screw Inc. of Totowa, New Jersey, for expertise on equipment for handling bulk powders to see what was needed and what could be shipped within a week. The company offered a volumetric screw feeder with variable speed drive and a controller with 4-20 mA remote speed input, which would allow the lime feed to automatically adjust to the changing pH of the influent. The higher the acidity, the more lime was continuously fed. The system would also treat the heavy metals